High strength steels for the automobile industry

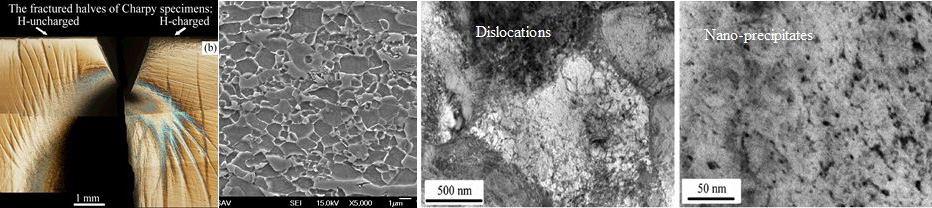

Research is carried out with the purpose of lowering the weight of the body of automobiles, while the current aim of the development of ultra high-strength double phase steels with emphasis on its good weldability, problem-free application of protective Zn-coating, resistance against hydrogen embrittlement and higher toughness and fatigue resistance in comparison to the grades developed up to this point. Part of the research is the degrading effects of hydrogen, the development of local deformations and plastic zone in front of the face of initiated cracks on the samples with stress raisers and with the use of new testing methods focused on the study of local properties of materials.

Gradient materials for engineering applications

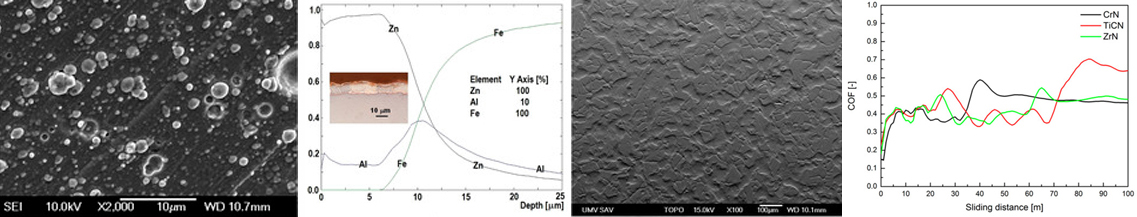

Research activities are focused on identification and testing the possibilities for lowering wear and increasing technological lifespan of innovative gradient materials of systems such as coating/substrate, overlay/substrate and the like. Areas of research are focused on material solutions for parts of forms for pressure casting Al-alloys, parts of shaping and machining instruments, and instruments for pressure bonding sheets.

Electrotechnical steels for electromobile and hybrid motors

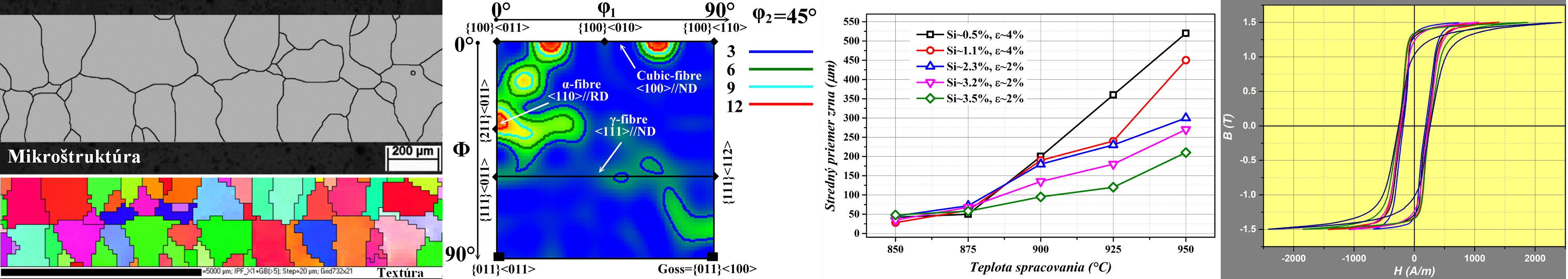

One challenge at present is the material development of newly-conceived electro-technical steels exhibiting a suitable combination of mechanical and electro-technical properties. The main goal of research is to propose and analyze a new design conception of the microstructure and substructure of high strength isotropic electro-technical steels, ensuring the combination of high strength and excellent electro-technical properties for use in the construction of rotor cores in electromobiles and for automobiles with hybrid drive. The research strategy is based on knowledge of the evolution and kinetics of structure-forming processes in electro-technical steels in the conditions of thermal-deformation activation.

Heat resistant steels and welding for high-performance energy boiler equipment

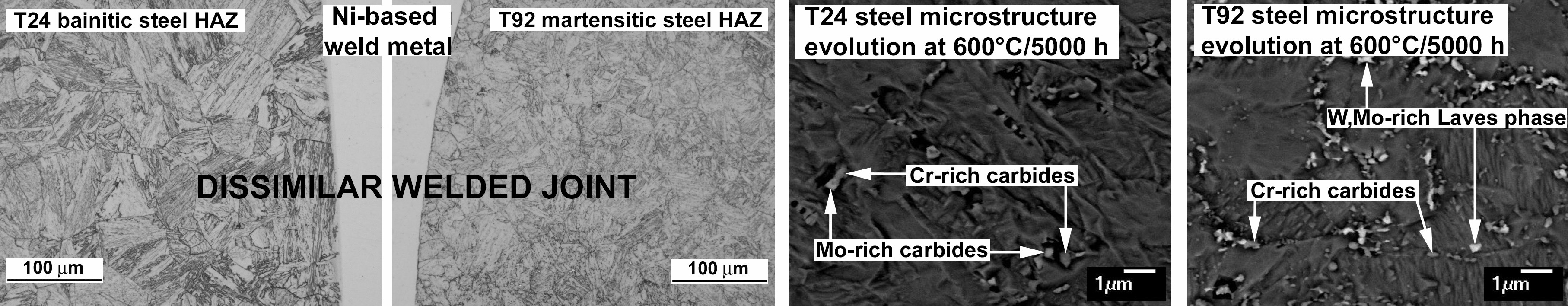

Increasing efficiency of energy boiler equipment in modern and ultra-supercritical power plants is contingent upon increasing the heat resistance of the construction materials used and their welded joints. Research activity is focused on studying the deformation and fracture processes of heat resistant steels and their weld joints in the conditions of high-thermal creep exposure, study of the degradation of mechanical and creep properties influenced by thermal exposure, investigating possibilities for optimalizing local microstructures and mechanical properties of heat-influenced areas of welded joints, and the use of innovative approaches of their thermal processing for the purpose of increasing the creep lifespan and resistance against thermal and hydrogen embrittlement.

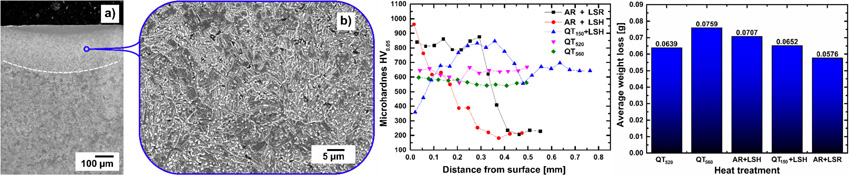

Steel for tools and metal-ceramic composites for demanding friction applications

Research activities are focused on innovative technological processes of heat treatment and modification of surface microstructures of modern tool steels with the aid of laser radiation for the purpose of improving utility properties including on the one hand sliding properties as well as resistance against various types of wear. The main aim of the research is optimization of the parameters of surface laser treatment of various grades of tool steels for work in heat and cold. Investigated at the same time are possibilities of increasing long-term stability of surface microstructures by supplementary technological processes. Studied in parallel fashion are activities oriented toward experimental development of new metal-ceramic composites for application mainly in the transportation industry. The aim is to improve and optimize the wear parameters by way of forming friction composites on the basis of metal-ceramic materials, prepared with the aid of powder metallurgy.

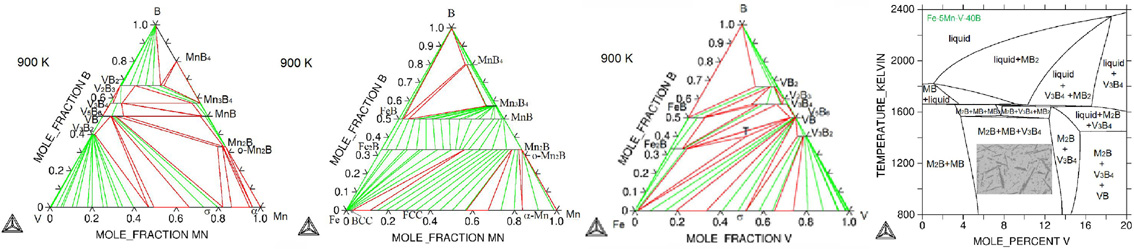

Modeling phase diagrams and the development of thermodynamic databases

There are modeling phase diagrams, the development and optimization of thermodynamic databases by semi-empirical method Calphad for ternary and consequently for more complex material systems. Developed databases enable the performance of all types of thermodynamic calculations for the given systems and all subsystems, i.e. enabling the determination of phase equilibrium, the number and chemical components of equilibrium phases, calculating values G, H, S, Cp and their dependence, drawing phase diagrams and their various sections, projection of liquid, etc., and this to the full extent of the chemical composition. Intensive research is done e.g. on ternary systems with boron (Fe-B-X, X= V, C, Mn, Cr, W,…) as subsystems of steels containing boron, then also borides of transition elements (application in the nuclear and chemical industries), compounds of boron and carbon (materials for cutting tools and armour). Research is also carried out in the area of complex metal alloys (for example the systems Al-Pd-Co, Al-Pd-Mo,…), where to this point there is very little information concerning binary subsystems.

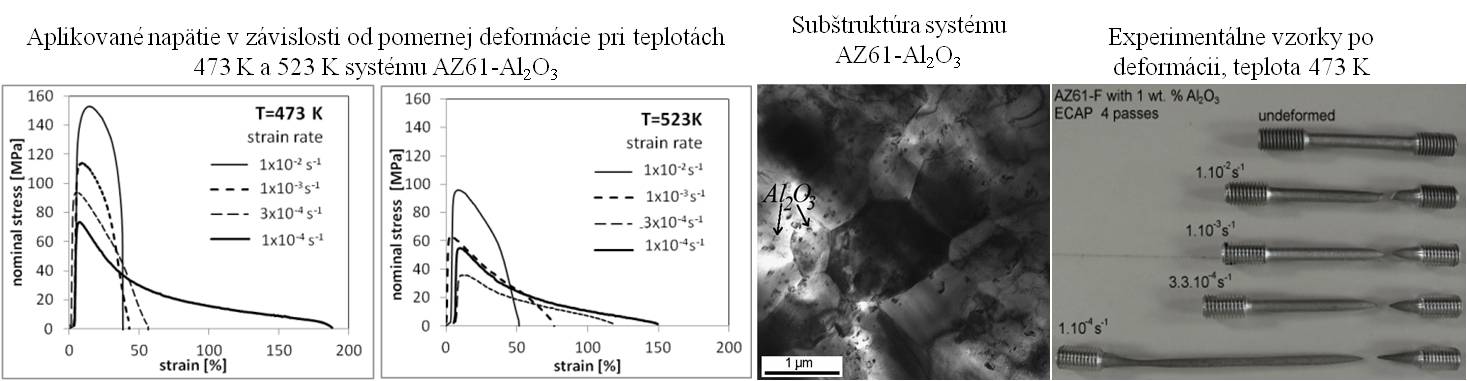

Nanocomposite materials on the base of magnesium alloys

Magnesium alloys are attractive materials for various construction applications. Improving their mechanical properties is possible with the addition of various particles, nanoparticles and carbon nanotubes (SiC, Al2O3, CNT) and by using methods of intensive plastic deformation (IPD). Current research is focused on the study of the creation of nanograins during the deformation process by the ECAP method. Changes have been studied in microstructures and substructures, physical and mechanical properties, mechanisms of failure and resistance of materials against wear depending on various production parameters and methods.

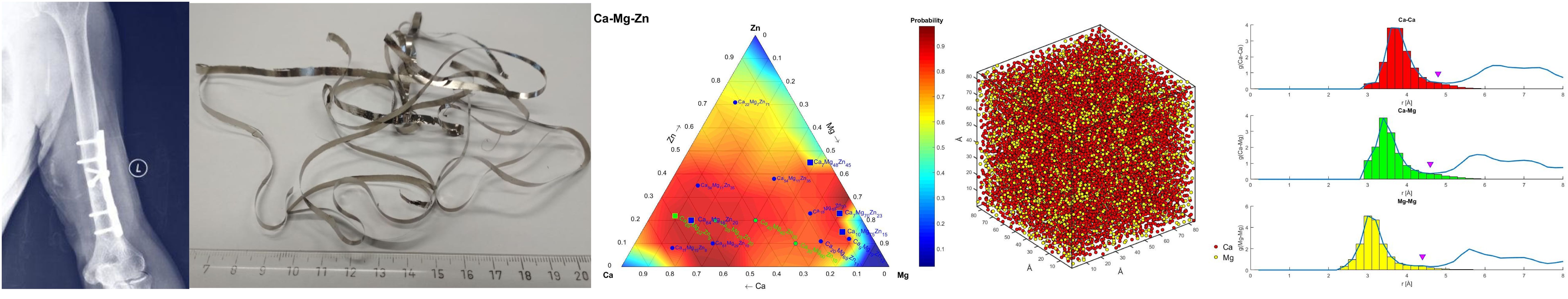

Biodegradable alloys

The alloys Ca-Mg, Ca-Zn, Ca-Al, Ca-Cu, as well as ternal alloys of the type Ca-Mg-Zn and Ca-Mg-Cu are characterized by the very small specific values (~2000 kg.m-1), the lowest among the metal glasses known to this point. Their model of elasticity (Young`s module) ~20-35 GPa is close to the values of the elasticity of human bones. Moreover, these alloys exhibit very low glass transition temperature Tg (~120-250 °C), during which they transform from the hard and solid state to the easily formable state, this caused by the plunge in viscosity of the alloys by several orders. From the perspective of their potential future use in medicine and surgery, it is very important that systems of the type Ca-Mg, Ca-Zn and Ca-Mg-Zn are comprised exclusively from biodegradable metals. Until now, measurements of these alloys were realized on synchronized instruments, diffraction and microdiffraction onP07/PETRA III and ID22 ESRF, spectroscopics on ID26 ESRF and neutron at the reactor in Budapest.

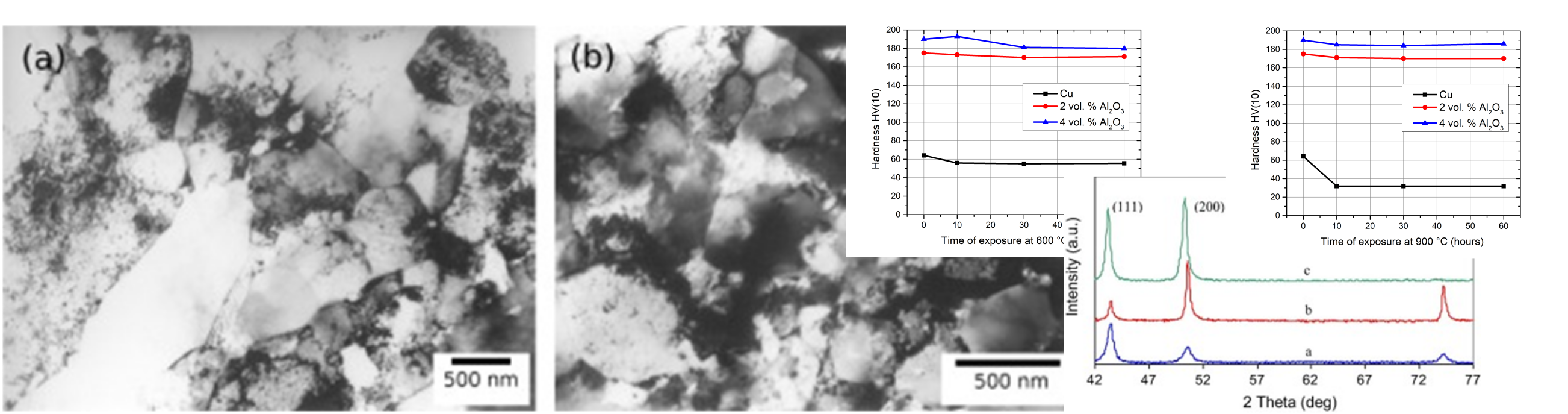

Disperse hardening of nanocomposite metal materials designated for high-temperature application

Composites comprised of a nanocrystalline metal matrix hardened by nanoparticles of dispersoids are quite promising materials, suitable for a great number of applications working at increased temperatures in the automobile, electro-technical and aviation industries. Currently under development in the world are various methods for preparing disperse-hardened materials. Their goal is to obtain high strength, temperature stable alloys with suitable physical properties. The goal of our research is the development of stable ultrafine structures of matrix powder prepared by progressive powder technology founded on the mechano-chemical processes, containing in one operation phase transformation precursors, refining the matrix and homogeneous distribution of secondary particles. Development is based on systems with a non-ferrous metal matrix, especially on a basis of Cu and AL. Research analysis of the mechanical and physical characteristics of the material with feedback on the structure leads to achieving through practice the required combination of properties of the composite. Material possessing the concretely required parameters can be used mainly for various high-temperature applications in the electro-technical industry (e.g. spot welding electrodes).

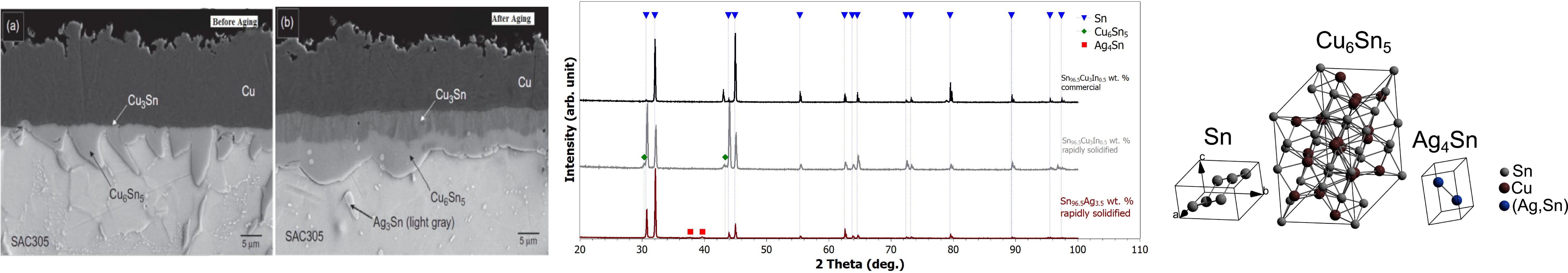

New types of lead-free solder

In the area of power electronics there is a constant search for new opportunities for creating quality connectors of components of power electronics, as well as for automobile electronics, which would be characterized by excellent dependability and a long lifespan without the degrading influence of intermetallic alloys, and this in the conditions of thermo-mechanical stress. The research and development of new non-standard types of soldering alloys on the basis of tin and non-typical microstructure may be included among the current challenges, for which the result may be new perspective materials with improved properties, which fulfill the requirements demanded of materials for power electronics. In this area we are preparing new types of lead-free solders with a higher proportion of intermetallic phases, which ensure excellent mechanical properties, at room temperature as well as in higher temperatures. Synchrotron research will be oriented on the characterization of the new alloys prepared and their bonding, and alongside that the demanding research characterizing the atomic structure of melts.

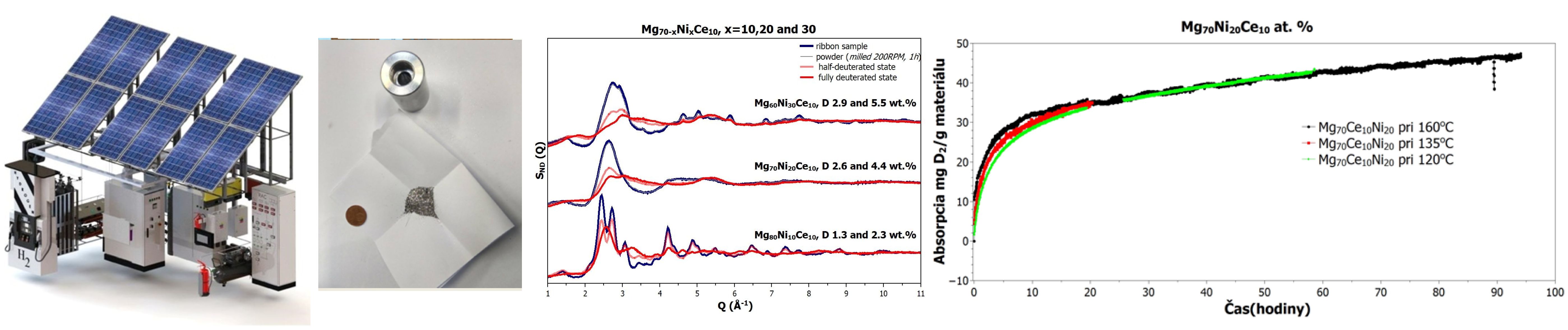

Metalhydride alloys for the effective storage of hydrogen

Storing hydrogen is a very important component in the system of hydrogen management. In current developments within the automotive industry and the wider application of hydrogen as a fuel intransportation, a key condition is increasing effectiveness when storing this gas. The aim of our research is the proposal and preparation of new types of metal hydride alloys, preferably by the rapid cooling method. Then we characterize complexly the macro and microstructure, the heat stability and mechanical properties of the metal hydrides we have prepared, and that with the standard methods used in materials research (illumination, scanning and transmission electron microscope, differential scanning calorimetry, x-ray diffraction, testing strength and hardness), and with the aid of synchrotrone radiation (x-ray diffraction x-ray radiation, in-situ high-temperature x-ray diffraction experiments, x-ray absorbtion spectroscopy) in European research centers such as DEY Germany, ESRF France or Diamond light source UK.

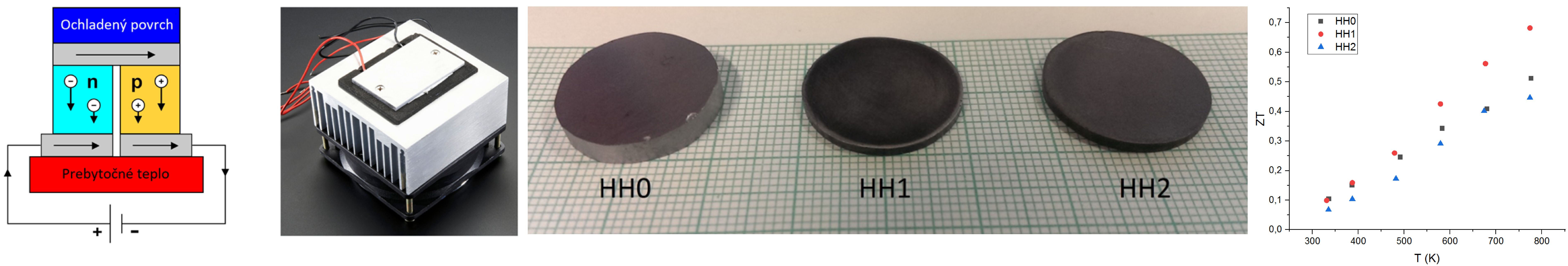

New types of thermoelectric alloys

Thermoelectric materials are a perspective area of today`s materials research. Materials able to effectively transform surplus energy from Earth, or rather lost energy from industrial production into the form of electrical energy, are much in demand today. Research in this area will be conducted in the area of research and development of materials with complex metal or metal-oxidic structure. In the future for this project we would like to gain the support of international projects in the challenges of Horizont 2020, ESA (European Space Agancy) grants, as well as projects of the type M-ERA.NET.

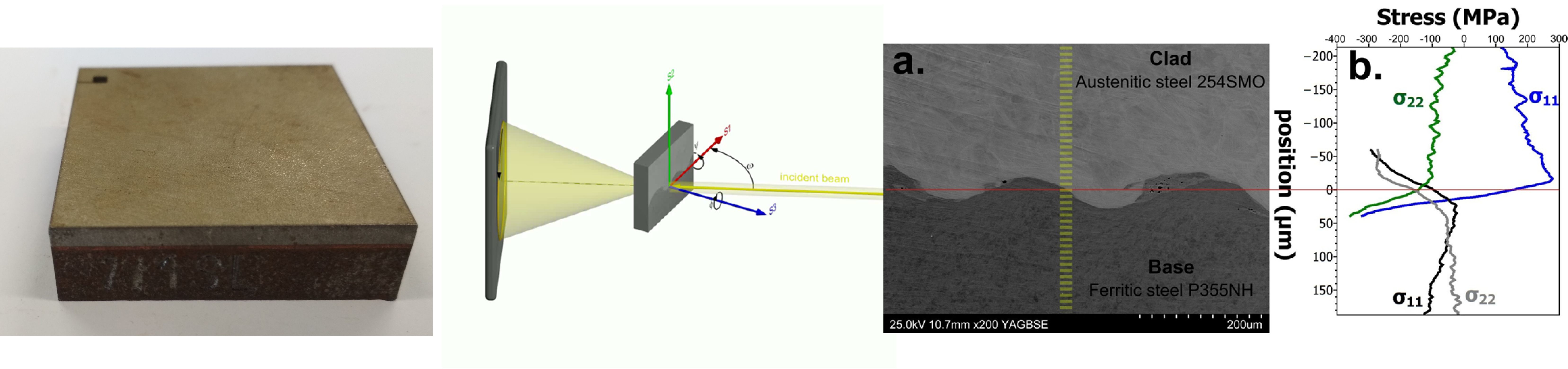

Stratified materials for geothermal applications

There is a characterization of new types of stratified materials prepared by explosive welding. Materials prepared by this technology (able to join materials of very different types of metal and alloys) may have great potential to replace materials used today in highly corrosive environments of the geothermal industry, this for example in heat exchangers, expansion vessels, piping substations, etc. Regarding the large number of geothermal sources within our territory, such research is very interesting for the needs of the Slovak Republic. These materials also find application in the food processing and petrochemical industries.

Contacts

Contacts Intranet

Intranet SK

SK