Preparation and production technology

SPS HP D10-SD – Spark Plasma Sintering

- Hydraulic press capacity 10 t [5 – 100 kN]

- Max. temperature 2200 °C, heating rate 5 – 1000 K/min.

- DC pulse source to 5500 A at 7,2 V

- Max. continuous power 37 kW

- Impulse timing 1…255 ms, break timing 0…255 ms

- Process gases – Ar, N (max. 5 bar)

- Vacuum at room temperature 5×10-² mbar

Melt Spinner SC – Rapid solidification of melts

- Cooling rate up to 105 oC/s

- High-vacuum system 2.10-5 mbar

- Induction melting 5-10g batch

- Process temperature up to 1800oC

- Temperature measurement – pyrometer

- Melt spinning – melt jetting on Cu roller, Ø200 mm, rotating speed up to 4200 ot/min

- Die casting to cooled Cu mould – ingots Ø3mm a Ø5mm, l = 200mm

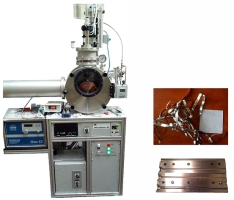

Arc melting furnace MAM-1

- Mini Arc Melter MAM-1 arc melting of 5-20 g batch

- Melting temperature up to 3500°C

- Melting and casting to the shape of loaf

- Suction casting to cooled Cu mould, ingots ø 3 mm, l = 35 mm

NanospiderTM NS LAB

Nanospider is the device, which enables production of continuous random or aligned webs of fibers with different web area weight and different fiber diameters. It allows electrospinning of a wide range of materials (different types of polymers, including bio-materials), using various substrates. Composite polymer/inorganic fibers are used as the precursors of ceramic micro/nanofibers.

- Diameters: 50 – 700 nm (+/-30 %)

- Length: significant

- Vlákna: continuous, uniform

- Web area weight: od 0,03 g/m²

- Web thickness: 1 – 500 µm

- Effective width: 250 – 350 mm

Attritor 01 SERIES MODELS, 01-HDDM

- High-energy mechanical milling of powders (up to 1,4 l) dry or wet milling

- Milling in protective atmosphere (N2, Ar), oxidizing atmosphere (O2) or v reduction atmosphere (H2)

- Rotating speed up to 650 rpm.

Attritor HDDP 01

- High-energy mechanical dry or wet milling of metallic and ceramic powders

- Water cooling of milling jar

- Variable frequency drive up to 4200 rpm. for milling jar size 750 cm³

Vibrating bal mill – Lab Wizz 320

High energy milling, mechanical treatment of the particle size, intensive mixing, mechanical alloying and mechano-chemical synthesis

- Milling capacity to 160 ml

- 2 milling ports

- Freqency 1 – 30 s-1

- Timer 0 – 99 min

LabRAM Vacuum – Resonant Acoustic Mixer

Resonant acoustic mixing is technology which utilize low frequency acoustic energy for mixing of powders and liquids. Mixing process is non-invasive, size and shape of powder particles is not influenced by mixing. Tme mixture is not contaminated by abrasion of mixing jar. Advantages of this technology are high intensity, short process time and high reproducibility of the mixing.

- Mixing capacity up to 500 g

- Acceleration of mixed material up to 100 G

- Optional – vacuum mixing up to 866 hPa

- Digital control of acoustic energy intensity

- digital timer

LabTest 5.600 ZL – precision hydraulic press

Pressing equipment is suitable for shaping and consolidation of powder materials by pressing in closed die.

- Precision hydraulic press, capacity 600 kN

- Continuous driven movement 0,05 – 100 mm/min.

- Speed drive accuracy 0,5 %

- Resolution of traverse movement 10 microns

- Force-reading device 3-600 kN a 0,3-60 kN

- Shift and movement reading accuracy 0.1 microns

- High temperature chamber for warm compaction up to 300 °C

- Digital measurement and control unit for drive and processing of pressing process data

Microwave Sintering Equipments

Hamilab V3000 – multimode sintering system

- Microwave power output 0.2 – 2.85 kW continuously controlled automatically

- Maximum temperature in the process chamber 1600 ° C

- Temperature measurement by IR pyrometer

- Working atmosphere Ar, N, He, dry air

- Rotary sample holder, rotation 5 rpm.

- Working chamber diameter 500 mm, height 560 mm, casing cooled by water

Single mode sintering system with impedance analyzer

- Microwave heating the sample in a silicon tube

- Chamber diameter 28 mm, height 80 mm

- Temperature up to 1250 ° C

- Pyrometer temperature measurement

- Real time measurement and analysis of absorbed and reflected microwaves

- Visual inspection of the sample during the process

- Manually controlling the absorbed microwave radiation intensity in the sample

- Protective working atmosphere Ar, N, air

- Measuring and analyzing the temperature profile of the sample using a real-time thermal imager with recording capability

CARBOLITE – tubular sintering furnace

- Electric furnace with SiC heater to Tmax. = 1500 ° C

- Sintering of both metal and non-metallic powders

- Sintering in vacuum (up to 8 mbar), inert (N2, Ar) and reducing atmosphere (H2, H2-N2)

- Tube diameter 90 mm

- Uniform heating zone length 450 mm

- PID controller (8 segments with customized self-timer temperature ramp)

- Monitoring of furnace air quality, O2 content analysis (0-10,000 ppm), RB measurement (-100 – +20 ° C)

- Continuous monitoring of active atmosphere components throughout the sintering cycle NDIR CO2 analyzer (0-5000 ppm), CO (0-3% vol.) And O2 (0-10000 ppm)

Vacuum dryer Binder VD 53

- Plug-in grids for fast heat transfer from heated chamber walls through sample grates and homogeneous temperature distribution in the chamber

- An aeration valve and the possibility of supplying air or inert gas

- Pressure 0.01 mbar

- Adjustable temperature up to 200 ° C

Glove Boxes

Jacomex G (save)-T2+2

- Glove box with adjustable negative pressure up to 10 mbar

- Airflow capacity 50 m³ / h.

- Internal and external HEPA filters

- Stainless steel construction

Terra Universal S100

- Glove box with positive inert gas pressure max 7 bar

- Inert gas flow 0.95 – 9.45 l / min.

PVD coating equipment

Cryofox Discovery 500

- PVD device with HiPIMS and DCMS sources after technical evaluation

- 3 unbalanced magnetrons (2 focused) with DC and HiPIMS sources

- Rotating holder with underfloor heating up to 500 ° C and pulse bias up to -1400 V

- Reaction sputtering (N2, C2H2, H2, O2, etc.)

PQL S500

- HiTUS technology for sputtering thin films and coatings

- Four 100 mm diameter targets with RF source for conductive and non-conductive materials

- Rotating holder with underfloor heating up to 500 ° C and RF prestressing up to 500W

- Reaction sputtering (N2, C2H2, H2, O2)

- In Situ measurement of substrate temperature, sputtering rate, residual gas composition and plasma composition (optical spectroscopy)

TRUMF laser device model TruLaser Station 3003 with TruFiber 400 source

- Laser Scribing for influencing the size of magnetic domains

- Laser microstructure of material surfaces

- Creating layers on metals and ceramics (Laser Cladding / Sintering)

- Alloying of materials (Laser Alloying)

- Precision micro-welding / soldering of metals / ceramics / plastics

- Precise micro-cutting

- Precise laser marking and engraving of materials

- Quenching / thermal treatment of material surfaces

LAC chamber furnaces with program regulator

- Electrical resistance furnaces up to Tmax = 1280 ° C for heat treatment of metallic and non-metallic materials

- Hardening and tempering of iron-based alloys

- Long term thermal exposure

- Implementation of complex thermal cycles

- Output from controller to PC (time recording)

EIR-EMO2 – Electro-spark cutting machine

- A four-axis wire cutter with a large feed range and high positioning accuracy

- Two-way cutting of workpieces (cutting of different shapes in the lower plane X, Y and upper plane U, V)

- Management software

- Maximum workpiece weight: 50 kg

- Slide range X x Y x Z 380 x 270 x 120 mm

ESCO II BSC – Laminar Box

- BSC Class II Laminar Box for Sterile Work Activities

Memmert INCO153 – Incubator

- Memmert CO2 incubator for cell culture

Microm SA-260 MA – sterilizer

- Automatic autoclave sterilizer for sterilization of samples and laboratory aids

Hettich Micro 220 R – Centrifuge

- Centrifuge for separation of chemical and biological mixtures

Preparation of preparations for material analysis

Metallographic grinder and polisher Phoenix 4000

- The device is used for sample preparation for light microscopy and pretreatment of samples for scanning and transmission electron microscopy

LectroPol-5 Electrolytic Polisher

- Equipment for electrolytic polishing and etching of metallographic samples of materials (eg for SEM and EBSD analysis) that are resistant to commonly used chemical etchants

Ion cutter 682 PECS

- The device is designed for cutting, etching and coating samples with ion beam. The device is used to prepare samples for electron microscopy e.g. for applying various conductive elements to the surface of the SEM, TEM, and EBSD assay samples

Llyophilisator ilShin

- The ilShin freeze dryer with evaporator up to -50 ° C

- Drying under reduced pressure 5mTorr

- Lyophilization of biomaterials or biological preparations, non-toxic powder materials

Electron microscopes

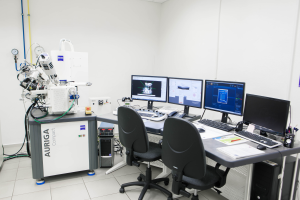

SEM / FIB – CrossBeam system AURIGA Compact

- SEM (scanning electron microscopy)

- Resolution 0.9 nm at 30 kV (STEM mode), 2.5 nm at 1 kV

- Magnification 12x-900,000x

- FIB (Focused ion beam)

- 5 nm resolution (30 kV, 1 pA)

- Magnification 600x – 500,000x

SEM EVO MA15 – Environmental Scanning Electron Microscope

- W fiber

- SE and BSE detectors for work at elevated pressure

- Range of working pressures in the chamber up to 400 Pa

- 5-axis motorized table

- Great Chamber

- Oil-free vacuum

SEM Jeol JSM 7000F – Scanning Electron Microscope

- Resolution: 1.0 nm (15 kV), 1.4 nm (1 kV)

- Magnification: from × 25 to × 1,000,000

- Voltage: from 0.1 kV to 30 kV

- Detectors: EDS, EBSD

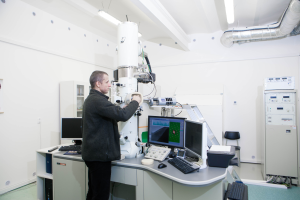

TEM JEOL JEM-2100F UHR – Transmission Electron Microscope

- Point resolution of 0.19 nm

- Lens with a spherical defect coefficient of 0.5 mm

- Schottky type FEG cathode

- STEM light field detector

- STEM dark field detector / HAADF mode

- EDS detector Oxford instruments X-MAX 80 mm2

- Gatan Orius SC1000A Digital Camera

- Tilt bracket +/- 60 ° JEOL

- Holders with JEOL sample rotation

- Electromagnetic shielding ETS-LINDGREN EMFC-MK IV

Light microscopes

Nikon ECLIPSE-LVDIA – automatic motorized optical microscope

- Observation methods: reflected and transmitted light, bright field, dark field, fluorescence, polarized light, differential interference contrast

- Optical magnification of 50, 100, 200, 500 and 1500x

- DS-Ri1 CCD camera with Peltier element, maximum resolution 4076 x 3116 pixels, 12-bit converter, exposure time 1 / 1000-600 sec.

- Automatic programmable feed in XY and Z directions

- Automatic focusing, automatic linking of series of images

- 3D image reconstruction by joining Z-sections using Nikon EDF (Extended Depth of Focus)

- Image measurement and analysis by NIS-elements

Nikon MA200 – inverted metallographic microscope

- Observation methods: reflected light, bright field, dark field, polarized light, differential interference contrast

- Optical magnification 50, 100, 200, 500 and 1000x

- DS-Fi2 CCD camera maximum resolution 2560 x 1920 pixels, 8-bit converter, exposure time 1 / 13000-60 sec.

- Manual control of XY and Z feed and focus

Nikon SMZ18 – Light Stereomicroscope

- Zoom range 0.75-13.5x

- Smooth magnification 3.75-135x

- Segmented ring LED lighting with continuous light intensity control

- DS-Fi2 CCD camera maximum resolution 2560 x 1920 pixels, 8-bit converter, exposure time 1 / 13000-60 sec.

- Autofocus and 3D image reconstruction (Nikon EDF)

Light microscope with Linkam TS 1400XY high temperature chamber

- Materials Spreadability Analysis

- Analysis of material transformations in the heating and cooling process

- The maximum working temperature of the chamber is 1400 ºC

- Heating rate up to 200 ºC / min.

- Cooling rate 240 ºC / min.

- The digital camera allows you to save individual images or video process

Stemi 2000 C – Stereomicroscope

- Stereomicroscope for fast surface observation in the range of 0.65 – 50 x with CCD camera and focal length up to 92 mm

Axio Observer 1M – inverted optical microscope

- Modern light microscope with 25x – 1000x magnification range for light field, dark field, polarized light and differential interference contrast mode

Neox Plu – confocal microscope / optical profilometer

- Dual illumination with both white and short wave monochrome light

- Automatic switching between confocal and interferometric mode only by changing lens and switching software

- Vertical resolution in PSI mode <0.02 nm

- Linearity deviation in vertical scanning range up to 50 <m <60 nm

- Vertical resolution in VSI mode <1.5 nm

- Shooting speed in confocal mode> 10 frame / s

- Interferometric lenses with magnification ranging from 2.5x to 100x

- Confocal lenses with magnification ranging from 5x to 150x

- Optical surface observation in light field in real colors

- Motorized and piezo-shifted in Z-axis and motorized XY-stage

- Manual transverse and longitudinal tilt of the table

- Software to automatically map and compose images from specified areas and to evaluate topographic surface parameters

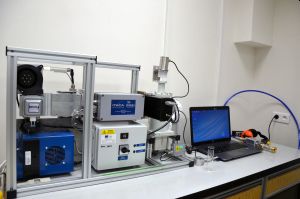

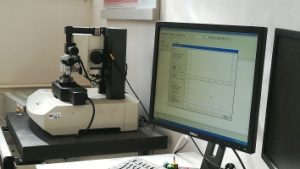

XploRA – Raman microscope

- Automatic laser switching and automatic calibration

- Automatic confocal aperture adjustment

- Spectral resolution at 2400 scratch / mm and laser wavelength at least 3.4 cm-1

- Wavelength range at 2400 scratch / mm and 532 nm wavelength from 200 to 3000 cm-1

- 4 automatically switchable spectrograph grids

- Automatic mapping with 1 point capture time below 100 ms / point

- Step XY stage less than 0.5 µm

- Evaluation software with a basic database for spectrum identification

- Optical microscope lenses with 10x, 50x and 100x magnification

- Color CCD camera with min. 1 mil. pixels

Olympus GX 71 – light metallographic microscope

- Olympus GX 71 digital light microscope (with camera), with maximum 2000x magnification. Light microscopy is used for basic microstructure analysis of materials with the possibility of observation in modes: light field, dark field, polarized light and Nomarski contrast

Leica DM IL LED – a biological light microscope

- Inverted light optical microscope with fluorescence function for observing the structure of biomaterials and cell cultures

X-ray diffraction analyzers

Philips X`Pert Pro – analytical diffractometer

- Philips X’Pert Pro MPD with ultra-fast X’Celerator as well as scintillation detector. Measurement Options in Bragg-Brentano Geometry in Various Variations: q-q; n-q. The device allows to analyze the phase composition (crystallographic characteristics) of the substances, the presence of the present phases in the material, the size of the crystallites and the macro / micro-stresses (measurement of residual stresses by the sin2y method). It also enables the realization of in-situ experiments using the HTK16 high-temperature chamber

Thermal analysis

Perkin Elmer DSC 8500 Differential Scanning Calorimeter

- Temperature range: from -180 ° C to 750 ° C

- Heating speed: from 0.01 to 750 ° C / min

- Cooling speed: from 0.01 to 750 ° C / min

- Temperature accuracy ± 0,05 ° C

- Cooling time from +100 ° C to -100 ° C with CLN2 cooling system: 80 s

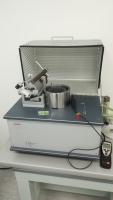

Jupiter STA 449-F1 Series DTA-DSC-TG Thermal Analyzer

- Temperature range: from 25 ° C to 1550 ° C

- Heating rate max. 50 K / min.

- Heating rate max. 1000 K / min.

- Temperature resolution 0.001 K

- DSC enthalpy accuracy ± 2% (for most materials)

Electrical and magnetic measurements

HP 4294A Impedance Analyzer

- Analysis of complex permittivity and permeability of materials

- Range from 40 Hz to 110 MHz

- Accuracy 0.08%

- Built-in calibration and compensation functions

Teraohmmeter Sefelec M1501P

- DC measurement of powder and compact material resistance

- Teraommeter – measuring range from 3 kOhm to 2000 TOhm (shielded chamber measurement)

- Measuring voltage 1-1500 V

- Accuracy 0.2%

- Range of picoampermeter 0,0, pA – 20 mA

- Sefelec BEM24 calibration box, 23 resistors from 5 kOhm to 100 TOhm with temperature and humidity measurement

- Multimetern 6 1/2 digit Keithley 2100 – range 100 microOhm – 100 MOhm

- Multimeter 7 1/2 digit Keithley 2010 – range 1 microOhm – 100 MOhm

Wattmeter Zimmer LMG500

- Measuring watt losses of materials, ferrite cores, transformers, electric motors

- Frequency bandwidth 0.05 Hz – 10 MHz

- Accuracy 0.025%

- Dynamic measuring range 3 – 1000 V, 20 mA – 32 A

- Rigol D1202CA – 200 MHz digital oscilloscope

DC resistance measurement Mitsubishi Loresta AX

- 4 point resistance measurement method

- Linear probing probes

- Measuring range from 10 mOhm to 10 MOhm

- Accuracy 0.5%

Measurement of coercive force DX-320

- Measuring the coercive force of the magnetically soft materials

- Measuring range 1 – 8000 A / m

- 2% accuracy

- Maximum magnetic field 30 kA / m

AFM Dimension ICON – Atomic Force Microscope

- Motorized equipment moving along the XY axis

- Samples with max. radius 120 mm

- Scanning area 100 × 100 μm

- Low noise, cover lid

- Video: 508 – 4010x

- Scanner – a device moving in three directions

Spectrum analyzers

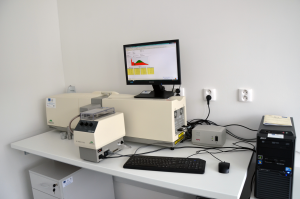

GD – Profiler 2 – optical emission spectrometer

- Polychromator 0.5 m

- Monochromator

- Detectors for 31 spectral lines

- Nitrogen generator

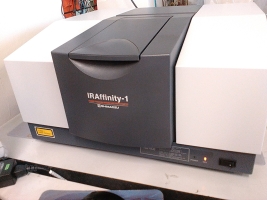

IRAffinity-1 Shimadzu – FTIR spectrophotometer

- ATR ZnSe FTIR Measurement of Surface Films

- Complete evaluation software

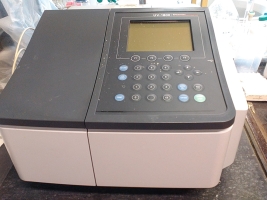

UV 1800 Shimadzu – UV VIS Spectrophotometer

- UV VIS dual-beam spectrophotometer

- Range 1100-200 nm

- Micro cuvette attachment (70 µL)

- Measuring the kinetics of reactions and enzyme activity in the temperature cell

HPLC / GPC system

- Watrex HPLC / GPC System with IR and UV VIS Detector (4 Channel) and Clarity Workstation for Molecular Weight and Composition Analysis of Biopolymer Systems, Proteins, Polysaccharides

Mastersizer 2000 E – a particle size laser diffraction analyzer

- Sampling – dry feeder Scirocco 2000M with automatic detection

- Measuring range -0.02 – 2000 micrometers

- Red light source – helium-neon laser

- Blue light source – a stiff source

- Automatic calibration and adjustment of the optical system

- Detection system red light – direct scattering, side scattering, backscatter

- Blue light detection system – wide-angle direct and backscatter

AccuPyc II 1340 – automatic device for measuring density

- Working medium Helium (possibility to use Ar, N, CO2)

- Replaceable measuring cells of 10; 3.5 and 1 ml

- High measurement accuracy ± 0.02% of nominal cell volume

- Automatic repeat measurement

- Automatic statistical evaluation and reporting system

Mechanical tests

Electro-mechanical universal testing machine Instron 5985

- Low profile force head, static, capacity: ± 250 kN

- Pneumatic clamping head capacity 200 kN

- 1930 mm vertical test area

- Max. sample thickness 40 mm, max. sample width 75 mm, max. sample diameter 50 mm

- Temperature chamber from -150 ° C to +350 ° C

- Dynamic strainer: direct measurement of elongation

- Feedback control of the machine (tensile, pressure and fatigue tests)

- Clamp length 12.5 mm with +/- 5 mm path (+/- 40% specimen extension)

- Temperature range of use of the strain gauge: -80 ° C to +200 ° C

TiraTest 2300 electro-mechanical testing machine

- Force sensors up to: 1 kN, 10 kN and 100 kN

- Universal material testing software for automatic data transfer

- A wide range of tensile, compression, bending, peeling, tear-off and friction applications

- Complies with ČSN, DIN, EN, ISO, ASTM and other industry standard test methods

- Temperature chamber F1200 up to 1000 ° C

- Furnace stretcher MFHT5 Lo 10-50 mm

Vickers 432 SVD Micro/Macro hardness tester

- Hardness tester for Vickers hardness according to EN-ISO 6507 with digital reading

- LCD display, online statistics

- Methods: Vickers & Knoop

- Load: 0.3 – 0.5 – 1 – 3 – 5 – 10 – 20 – 30 kgf

- Accuracy according to EN-ISO 6507, ASTM E384 and E92, and JIS

- Manual image processing and automatic imprint evaluation

WILSON-WOLPERT Tukon 1102 hardness tester

- Hardness measurement Micro-Vickers according to EN-ISO 6507 / ASTM E384

- Methods: Vickers & Knoop

- Load: 10, 25, 50, 100, 200, 300, 500, 1000 (2000) (gf)

- Standards: EN-ISO 6507, ASTM E384 & E92, and JIS

- Conversion to: Brinell, Vickers, Rockwell

- Manual image processing, including the possibility of automatic imprinting

- Motorized X-Y table controlled software

Universal hardness tester with max. load 250kg, model UH250

- Methods: Brinell, Vickers, Rockwell, S-Rockwell, Knoop, HBT

- Measurement evaluation using Wincontrol software

- Measurement according to ISO 6506, ISO 6507, ISO 6508, ISO 4545, ASTM E18, ASTM E92, ASTM E10 and JIS

- Load: 1, 3, 5, 10, 15, 15.625, 20, 30, 31.25, 50, 60, 62.5, 100, 125, 150, 187.5, 250 kgf

- Vickers Test Procedures-HV 1, 2, 3, 5, 10, 20, 30, 50, 100

- Rockwell Test Procedures-A, B, C, D, E, F, G, H, K, L, M, P, R, S, V, B, F, 15 T, 30 T, 45 T, 15 W, 30 W, 45 W, 15X, 30X, 45X, 15Y, 30Y, 45Y, 30TM, HMR 5/25

- Brinell Test Procedures-HB1: 1, 2.5, 5, 10, 30; HB2.5: 6.25, 15.625, 31.25, 62.5, 187.5; HB5: 25, 62.5, 125, 250; HB10: 100,250

Nanoindentation Tester Agilent G200

- Equipment for nanoindentation measurements (nano-hardness measurement)

- High precision measurements

- Testing from 0.5 mN to 10 N

- Dynamic mechanical analysis

- Scanning by tip

- Microscratch testing

- Testing up to 500 ° C

Micro-nano indentation tester TTX NHT

- Different tip geometry

- Load Resolution 40 nN

- Testing from 0.1 to 500 mN

- Dynamic Mechanical Analysis

- Indentual fatigue and creep

- Large range of load modes

BRUKER Scratch Tester

- Examination of coating damage mechanisms during wear

- Scratch test up to 200 N resistance – adhesion and stability of protective coatings

LECO LM700AT – automatic micro hardness tester

- Load: 10 g, 25 g, 50 g, 100 g, 200 g, 300 g, 500 g, 1000 g

- Lenses: 10x, 50x, 100x

- Tip: Diamond indentor Vickers

- Measuring microscope: electronic

- Automatic Penetration Evaluation – Conversion Table HV

Cracktronic – Resonant Fatigue Testing Machine

- Desktop model for dynamic bending load

- Application: fatigue tests, / S / N-diagrams; fatigue crack growth / da / dN-curve

- Max. bending moment value: 160 Nm

- Max. peak-peak bending moment value: 160 N (± 80 Nm)

- Max. static moment: 100 Nm positive moment

- Dynamic angle: 2 ° (± 1 °) adjustable

- Frequency range: 70-250 Hz (6 steps)

Nanotribometer CSM NTR2

- Extremely accurate measurements at loads up to 1 N

- Circular and reciprocal motion

- Accurate tests of small samples, biomaterials, polymers

High temperature tribometer CSM THT

- pin / ball on disk

- Load up to 10 N

- Tests up to 800 ° C

Universal tribometer Bruker UMT 3

- Wide range of exposure modes

- Circular and reciprocal motion

- Dry and Liquid Tests (Lubricant Tests)

- Bearing tests – balls, rollers

- Higher loads (5-1000 N)

Charpy’s hammer

- Dynamic bending impact tests

- For determining impact work and impact strength values

Creep machines

- Creep tensile tests of metallic materials under constant load

- Temperature range of tests from 200 ° C to 650 ° C

- Initial load voltage range from approx. 50 MPa to 200 MPa

- Possibility of continuous measurement of creep deformation by LVDT sensors with accuracy of 1 μm

- Possibility to determine creep lifetime (time to refraction) and creep plastic properties

HTTF-2 High Temperature Furnace

- Four-point creep bending, pressure and indentation creep up to 1500 ° C

- High temperature bending strength measurement up to 1500 ° C

- Measure crack growth at elevated temperature up to 1500 ° C

- Measurement of thermal shock resistance

Contacts

Contacts Intranet

Intranet SK

SK