Characteristic of the division

The division is concerned with specific physical, mechanical, biological and chemical properties characteristic for functional and multifunctional materials. The material bases are hybrid materials of various chemical natures, polmers and their mixtures, polymer-anorganic composites, metal-polymer materials, metal-ceramic materials. Research projects are focused on the study of synthesis and complex assessments of anorganic phases and hybrid composites with varied physical-chemical natures, while the designated aim of the research is the final application with concrete electro-physical, electrochemical, biomaterial, magnetic and mechanical properties. Orientation of the scientific output is focused on the relationship between the chemical composition, phase composition, structure and properties of the prepared materials as well as studying events influencing the relationships listed. Research and development is mainly on the growth of knowledge in the area of preparation of thin electroceramic layers, biomaterials designated for use in reconstructive and regenerative medicine, biomaterials for diagnostic purposes, multifunctional materials, soft magnetic composites, multisensor materials, high-strength sintered construction materials and composites.

Biodegradable sintered metal materials for temporary implants

Systems:

- on the base of iron: Fe, Fe-P, Fe-Mn, Fe-Ag, Fe-Mg, Fe-semiconductive metal oxides.

- on the base of magnesium: Mg, Mg-Zn, Mg-ZnO, Mg-Ca-Zn-ZnO.

Structures:

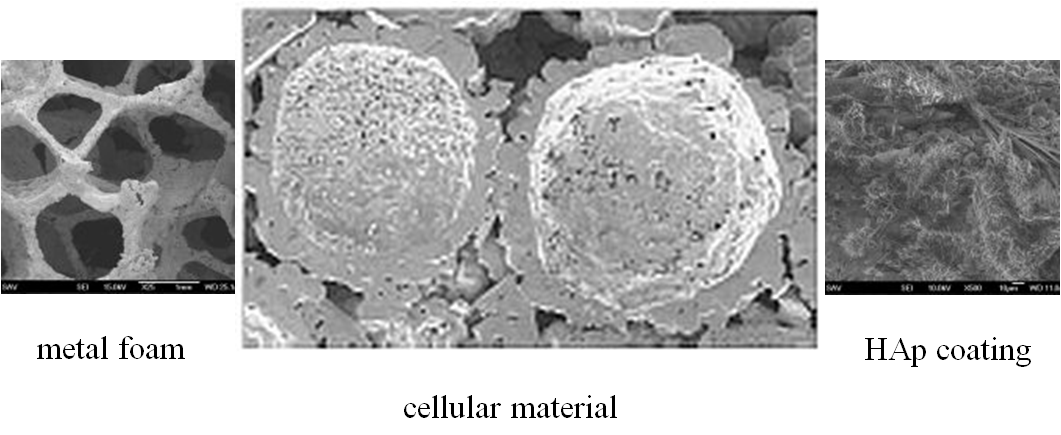

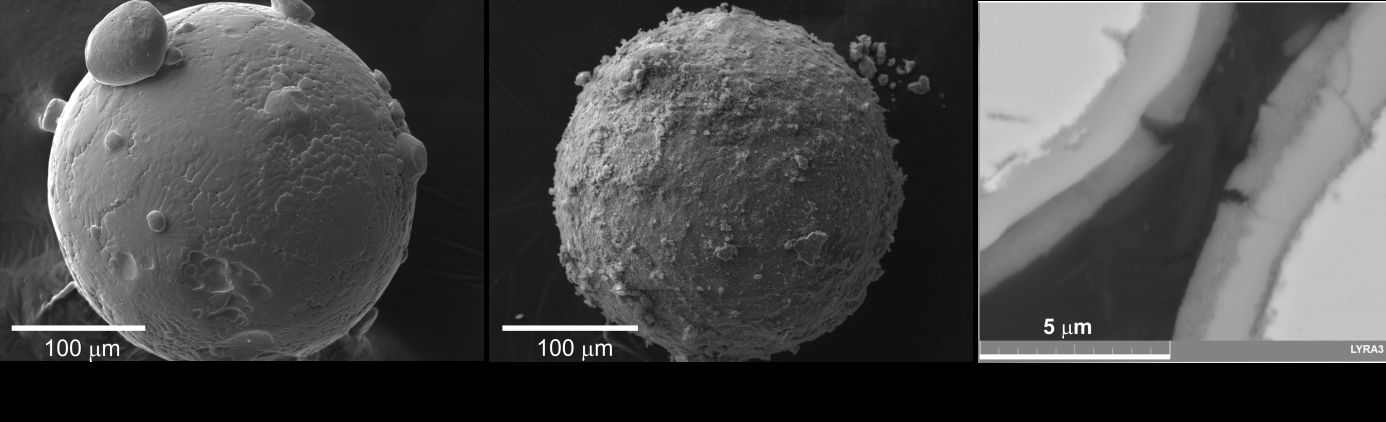

- compact: samples prepared by pressing and sintering full powder particles.

- cellular: samples prepared by pressing and sintering hollow powder particles.

- foam: samples prepared by replication method using polymer foam precursors.

Types of surface:

- bare metal surface: samples without surface prepartations.

- surface partly or completely covered in non-metal coating: samples with islets or coatings of bioceramics/biopolymers deposited on the metal surface.

Properties:

- mechanical properties: Young`s elasticity modulus, strength in bending and pressure, density, hardness and their changes as a result of corrosion.

- corrosion properties: character of corrosion, corrosion potential, corrosion speed.

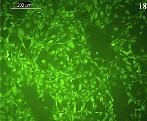

- biocompatability: hemocompatibility, cytotoxicity.

Preparation, characterization and application of compacted magnetic soft composites

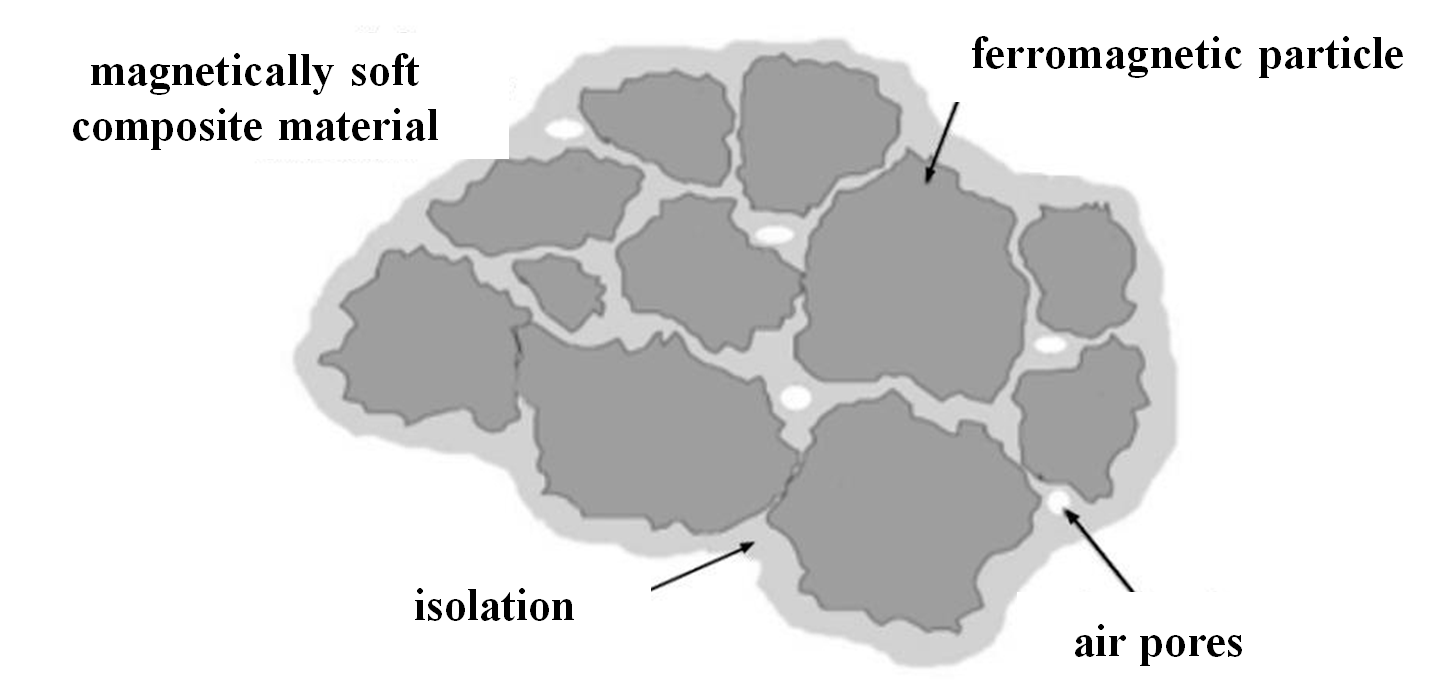

Magnetic soft composites prepared from powder ferromagnetic particles insulated by a thin layer of dielectric material are sought after these days for the purpose of producing three-dimensional (miniaturized) electromagnetic components, which require high frequency in an alternating magnetic field, which is the decisive parameter preparing a homogenous and highly adhesive coating, ensuring the high values of specific electrical resistance and permeability.

- The primary components of composites are ferromagnetic metals Fe, Co, Ni and their alloys. The secondary electro-insulation component is distributed in the form of a thin layer on the surface of ferromagnetic powder particles. Pressing and thermal treatment create microstructure of continual electro-isolating networks in the ferromagnetic matrix. The main idea is minimalizing the occurance of whirling currents in the alternating magnetic field with a higher than industial frequency.

- Composites are comprised of mutually electrically isolated magnetic particles, offering relative low energy loss in the area of medium high and higher magnetization frequencies thanks to the low losses of whirling currents (isolated layer between individual magnetic particles ensures minimum routes for whirling currents), relatively high magnetic induction saturation, isotropic behavior of physical properties and broad opportunities for producing 3D components by powder metallurgy technology.

- Applications of compacted magnetic soft composites are in the area of development high-frequency multipole electric motors, high-frequency inductors, electromagnetic shielding, etc.

Focus on three types of coating: organic, anorganic, and hybrid

Organic coatings are synthesized on the basis of phenol formaldehyde resins, anorganic coatings are presented as ferrite with a spinel structure and the hybrid is comprised of a combination of the two previous types in a suitable ratio.

Preparation of powder materials

- Powder metal, non-metal, composite and hybrid material designated for processing by compaction, or for use in powder form.

- Mechanical methods of alloying, adjusting the size and shape of the particles, mechanosynthesis, coating powder particles, homogenization of powder mixtures.

- Deagglomeration and homogenization of powder and liquid mixtures by resonant acoustic mixing, ultrasound homogenizer.

Characterization of powder materials

- Density of the powder, liquid and compacted materials by method of repeated weighing (Archimedes method) and helium pycnometry.

- Sized distribution of powder particles by laser diffraction method and the method of monitoring meshed powder materials.

- Qualitative and quantitative analysis of the shape and surface morphology of powder particles by methods of optical and electron microscopy.

- Analysis of the compressibility of powder materials, pressed curves of powder materials and mixtures.

- Analysis of sinterability of powder materials, sintering kinetics.

Progressive methods of compacting powder materials

- Uniaxial pressing in cold and in heat.

- Sintering by focused and scattered microwave radiation or traditional heating.

- Thermal processing of powder and compacted materials by microwave heating.

- Research and development of progressive methods of compacting powder materials – vacuum sintering, isostatic pressing, sintering by plasma explosion, microwave sintering, deposition powders, additive production.

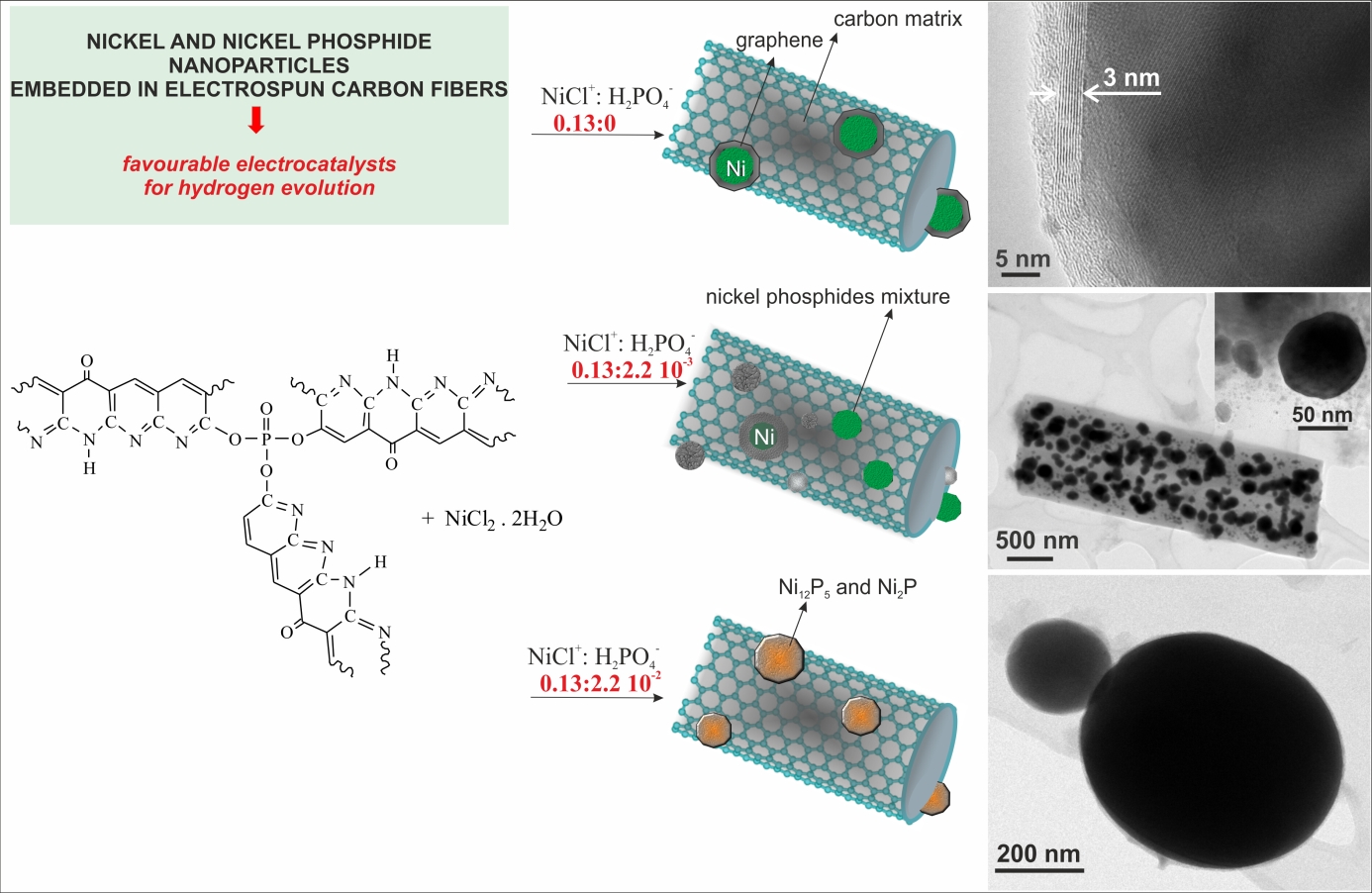

Carbon fibers with incorporated metal particles and phosphides of metals for electrocatalytic elimination of hydrogen

- The economic and health impact of using fossil fuels as the primary energy source leads to research and the implementation of long-term sustainable sources of energy without significant emissions and environmental problems. One of the possible forms of obtaining energy is HYDROGEN.

- Electrolysis of water is the most promising technology for producing hydrogen.

- Research is focused on preparing modified carbon catalyzers for electrolytic production of hydrogen.

- Fibers are produced by fiber production technology from the free surface.

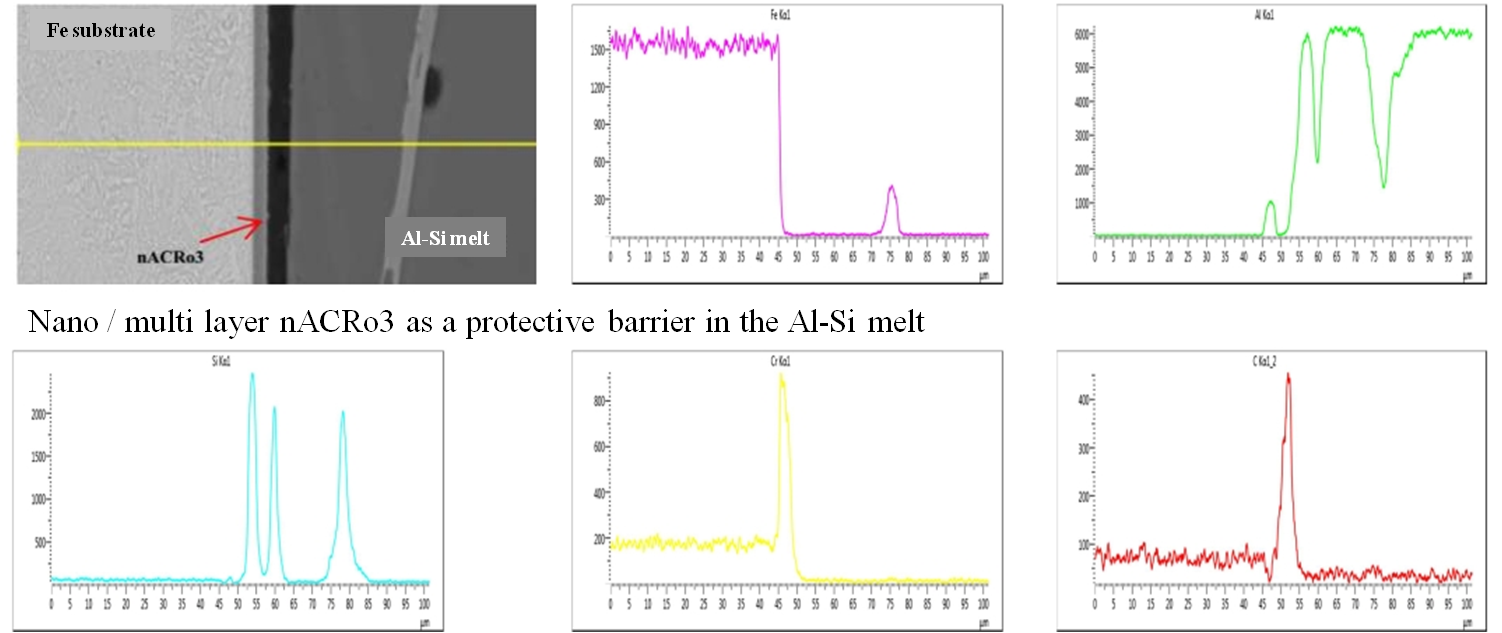

Processes of degradation of nano/multi composite coatings in the melt of foundry aluminum alloys

- Application of PVD nano/multi composite layers by duplex technology (PVD + plasma nitriding) to material from steel for hot working (moulds and their parts for pressure casting aluminium).

- Nano/multilayers create an effective barrier against crack propagation and defects in the exposed part of the material.

- Creating an effective protection barrier of materials/parts for testing in the environment of the Al-Si melt.

Laser surface treatment of tool steels

- Applying laser surface treatment hardens the surface of materials/tools without loss of inner strength.

- Improving surface and adhesive propertires.

- Creating a refined hard martensite/carbidic structure under the surface depending on the laser power.

- Increasing the lifespan of tool steels.

- Perfecting a component with idealized surfaces in most engineering applications.

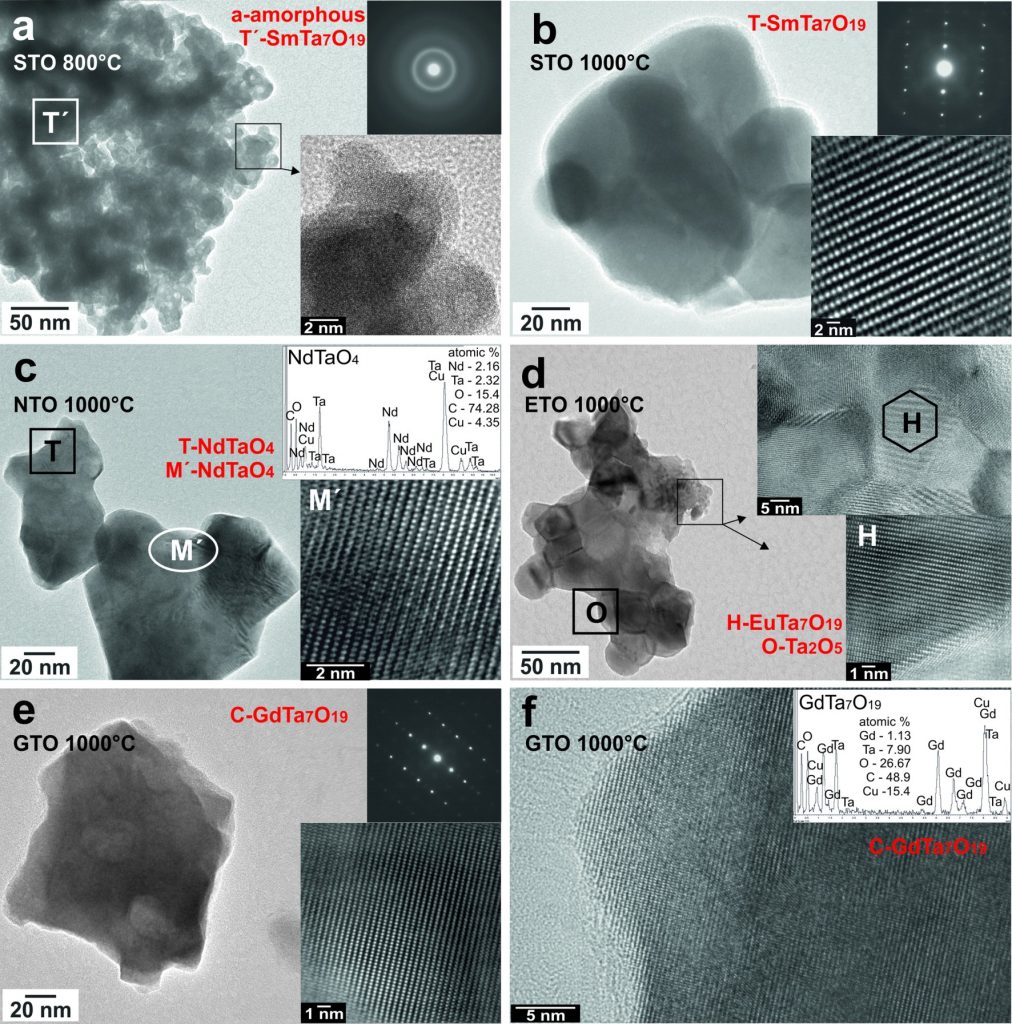

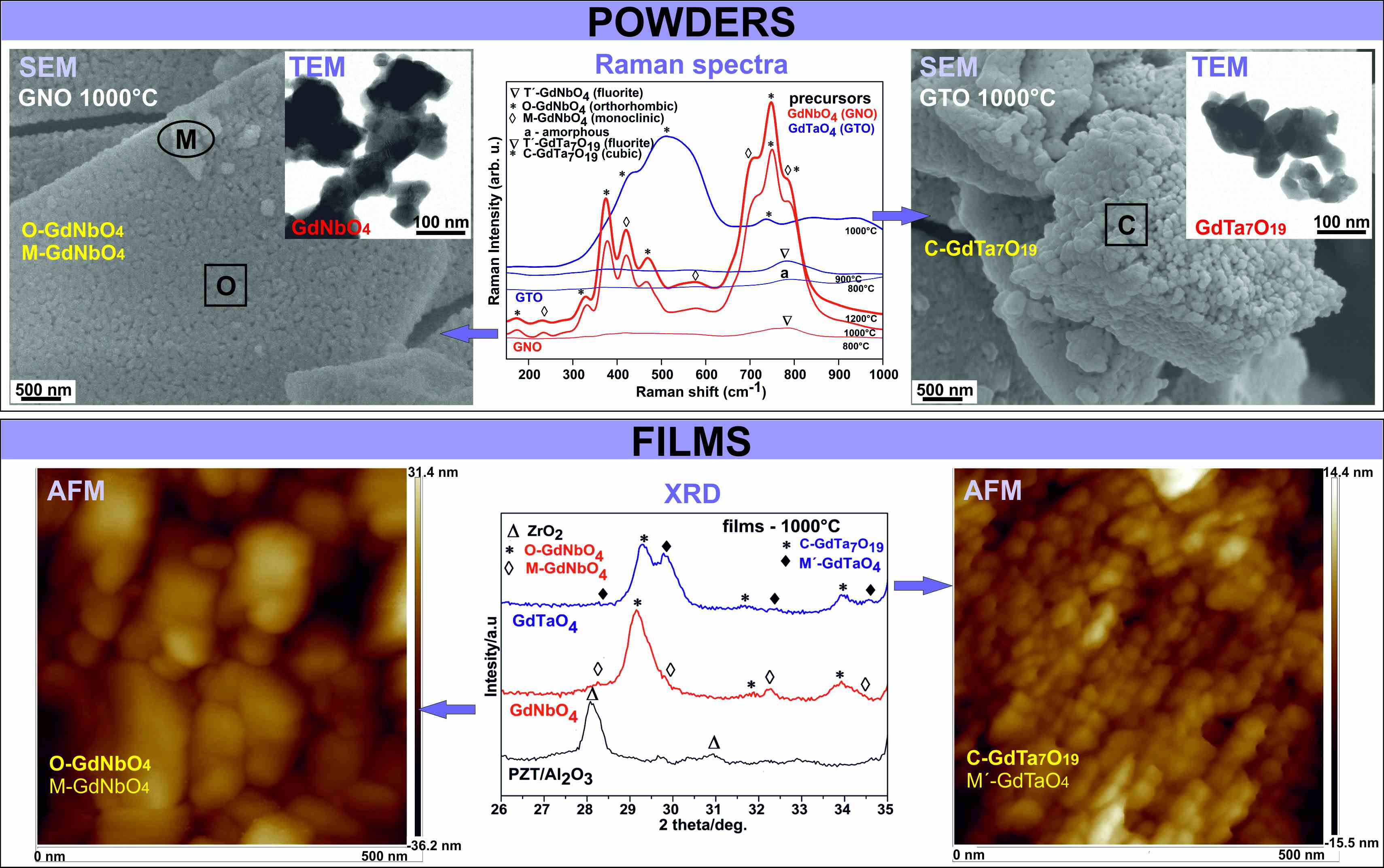

Materials on the basis of lanthanides

- Development of new methods in the basic research area of electroceramic materials, their treatment and characterization.

- Modification of sol-gel proceses of nanoprecursors, developing knowledge in the area of treating thin layers and films on the basis of lanthanide elements as well as developing experimental methods to investigate their phase composition, microstructure, physical and mechanical properties.

- Polymorphous powder LnNbO4 and LnTaO4 precursors on the basis of lanthanides (Ln = Nd, Sm, Eu and Gd).

- Phase transformations: fluorite phase (at 800 and 900°C), orthorhombic or tetragonal LnNbO4 (at 900°C), hexagonal or cubic phase (at 1000°C), monoclinic M-LnNbO4 (at 1000°C) and M‘-LnTaO4(at 1100°C).

- Transparent thin films (thickness ~100 nm) prepared by technology sol-gel/spin coating from corresponding solutions of sols on the basis of lanthanides applied to Al2O3and Si/SiO2 substrates.

- Use as a solid electrolyte for thin-film fuel cells and sensors.

Sol-gel/spin-coating method of preparing thin films

- Synthesis of LnNbO4 and LnTaO4 sols and taking into consideration use of a suitable concentration Nb and Ta on application of the Pechini method modified by us, employing the polymers Nb- and Ta- tartaric complex instead of the citrate method.

- Sol-gel process enables control of the stoichiometry, improving homogeneity and decreasing the heat of annealing materials as opposed to the conventional ceramic method of mixing oxides.

- Preparing thin films from the corresponding sols solutions on the basis of lanthanides applied to Al2O3 and Si/SiO2 substrates by spin-coating method.

- Thin films have varied polymorphous structures and mechanical properties.

- We focus mainly on the preparation of perovskite and pyrochlore niobic and tantalum thin films and determined the phase composition, we have developed and modified several methods of sol-gel synthesis Pb(Zr0.52Ti0.48)O3, KNbO3, NaNbO3, K0.5Na0.5NbO3, La0.33NbO3, La0.33TaO3, La0.5Nb0.5TaO3 doped Eu and LnNbO4 and LnTaO4, part of the research is also focused on synthesis of new precursors of thin films.

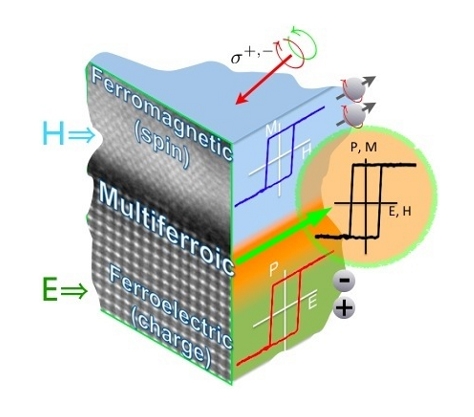

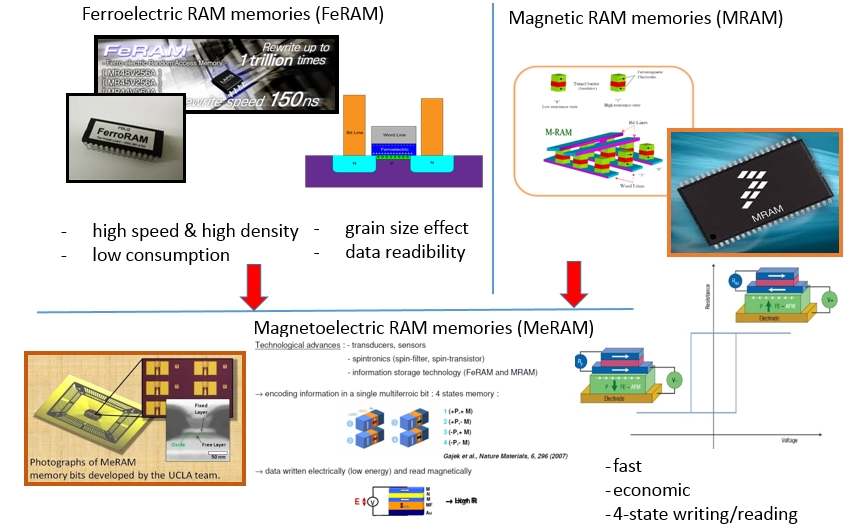

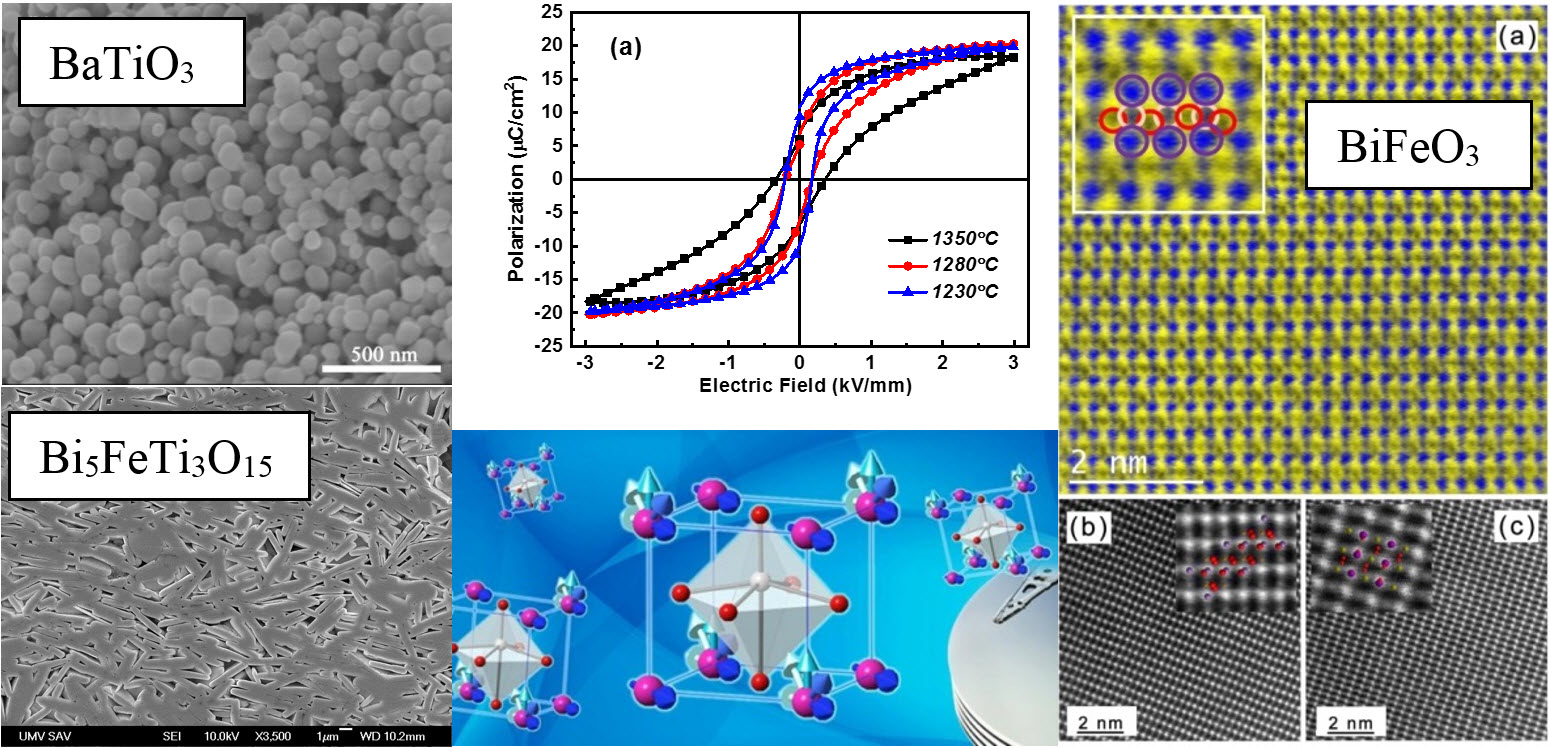

Ferroelectric and multiferroic materials

- Electric and magnetically active materials with hysteretic reaction to outer fields (electric, magnetic, mechanical).

- Use as sensors, actuators, accelerometers, convertors, RAMs, storing and converting electrical energy.

- Focused on perovskite oxides of the type Pb(Zr,Ti)O3, BaTiO3, Pb(Mg,Nb)O3, BiFeO3and stratified structures with Aurivillius phase of the type Bi5FeTi3O.

Biomaterials on the basis of calcium phosphates and composites with biopolymers

- Basic and applied research oriented on the preparation and characterization of biomaterials on the basis of biocements and composites. New biocomposite cement biomaterials are being developed on the basis of calcium phosphate with a biopolymer component with the aim of creating optimal systems from the viewpoint of microstructure and composition with suitable properties for application on various tissue defects.

- Synthesis of specific calcium- or magnesium- phosphate phases and preparing their mixtures for use as biocements in regenerative and reconstructive medicine (hard and soft tissue), dentistry, etc.

- Preparing implants for medical applications and in vivo tests.

- Phase, chemical, physical-chemical and material characterization of powder biocement mixtures.

- Characterization of properties of biocement systems.

- In vitro testing of cytotoxicity and other biological characteristics of cements.

- Preparation of composite systems on the basis of biopolymer mixtures with chitosan, polyhydroxybutyrate and other polysaccharides or protein types of polymer.

Contacts

Contacts Intranet

Intranet SK

SK