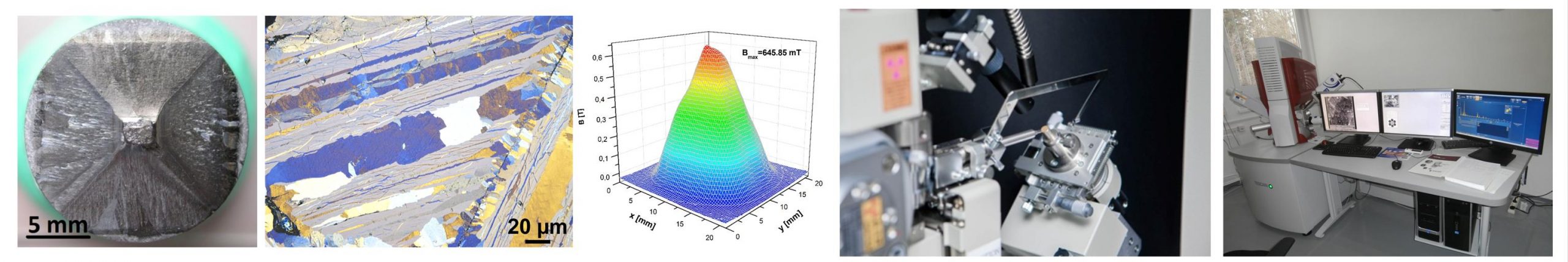

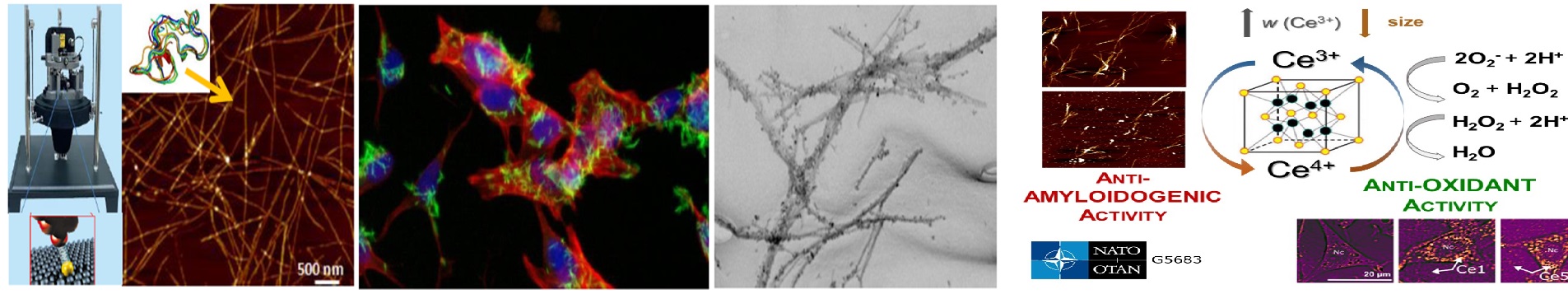

This Laboratory concentrates on oxidic functional ceramic materials. The Laboratory´s principal activities are preparing and studying the relationship between the microstructure and superconducting properties of YBCO massive single-grain superconductors (MSS). In this field the Laboratory has achieved scientific results valued in Slovakia and also abroad, developed wide international cooperation (ISTEC Tokyo, Argonne National Laboratory, USA, Oxford University, Cambridge University, IPHT Jena, IFW Dresden, ATI Vienna, ICMAB Barcelona, CRETA CNRS Grenoble) within multilateral projects (projects 5RP and 6RP) and built the infrastructure necessary for the research and development of these materials.

YBCO MSS (YBCO is the abbreviation for the high-temperature superconductor YBa2Cu3O7, referred to below as Y123) are suitable for practical applications mainly as superconducting permanent magnets. Part of their unique properties, as a consequence of strong pinning of magnetic flux lines, is their ability to trap one order higher magnetic fields than the best permanent magnets (up to 17 Tesla at 30 K temperature, even 100 times higher energy density), to levitate or suspend stably in an non-homogeneous magnetic field (high levitation force) and to move without friction in a homogeneous magnetic field. The main application possibilities are in the construction of efficient electric rotary machines, magnetic separators, levitation devices such as frictionless bearings, flywheel energy reservoirs, and magnetic levitation transport systems (e.g. MAGLEV trains).

High-temperature superconductors are generally characterized by small coherence length, a parameter which limits the maximum distance of electrons in a Cooper pair (2,7 nm at 77 K for Y123). This parameter fundamentally specifies requirements for the superconductor preparation technology, which must produce single-crystalline material with nanosized pinning centres.

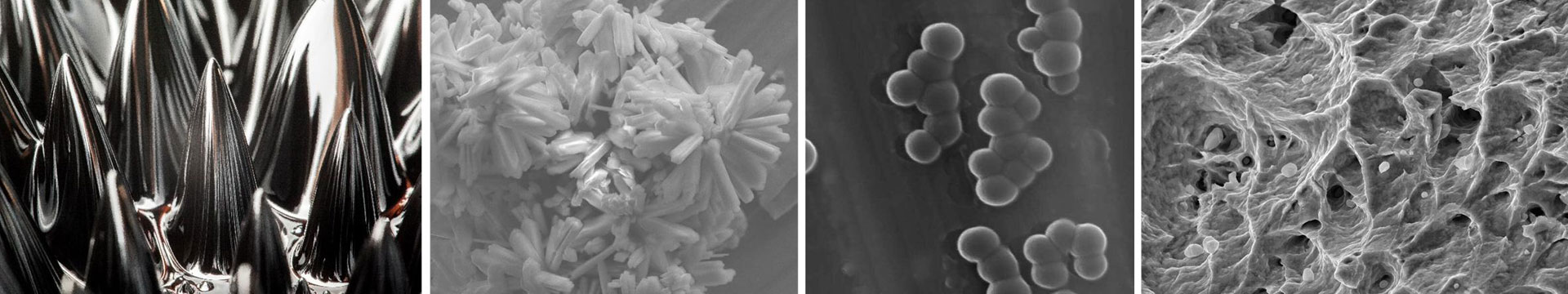

We can ideally imagine YBCO MSS (superconducting magnet) as a cylindrical YBa2Cu3O7 single-crystal with a diameter of 30 to 100 mm, in which the pining centres are scattered. These centres may be submicron particles of non-superconducting Y2BaCuO5 (211) phase (Picture 1), or the so-called chemical pinning centres: nano-sized areas with a distorted crystal lattice formed by substitute atoms.

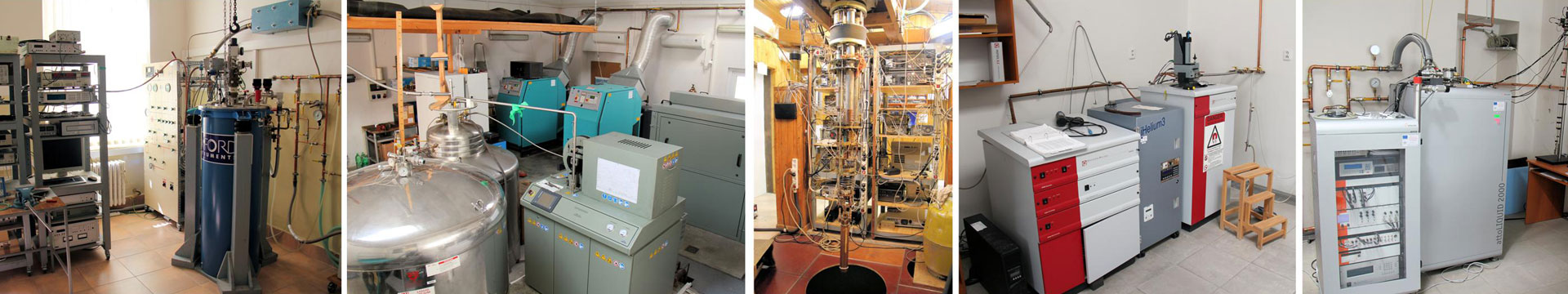

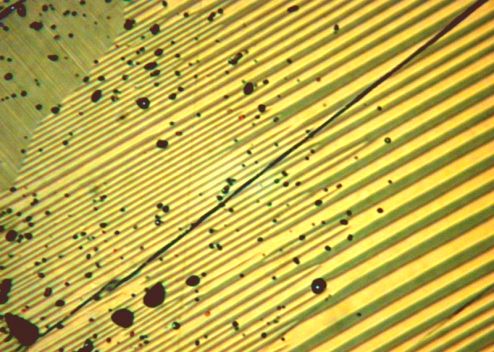

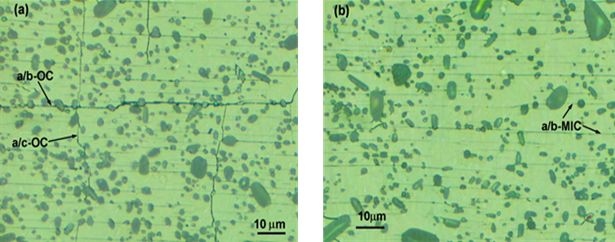

As grown massive YBCO single-grain samples prepared with so-called Top-Seeded Melt-Growth process have a low oxygen content and are non-superconducting. They must be oxygenated and, as we have shown, oxygenation cracks are created in this process as a consequence of shortening of lattice parameters (Picture 2). These cracks diminish the efficient sample cross section to one third, but are necessary for successful oxidation. If only bulk oxygen diffusion would provide oxygenation, the MSS oxygenation would last more than a thousand years. We have recently demonstrated that high-pressure, high-temperature oxidation may suppress the formation of oxygenation cracks and increase critical current density threefold (Picture 3). We have also found new possibilities of creating chemical pinning centres by microalloying.

Picture 1. 211 particles and twin structure

Picture 2. Formation of oxygenation cracks in YBCO MMS at annealing in oxygen at 400 °C

Picture 3. Increasing the critical current density by eliminating oxygenation cracks with high-pressure oxidation

Contact

Contact Intranet

Intranet SK

SK