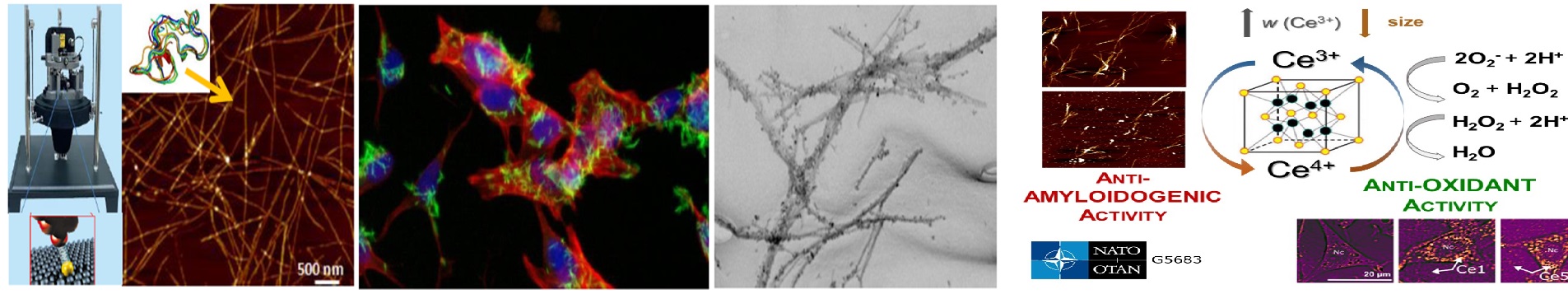

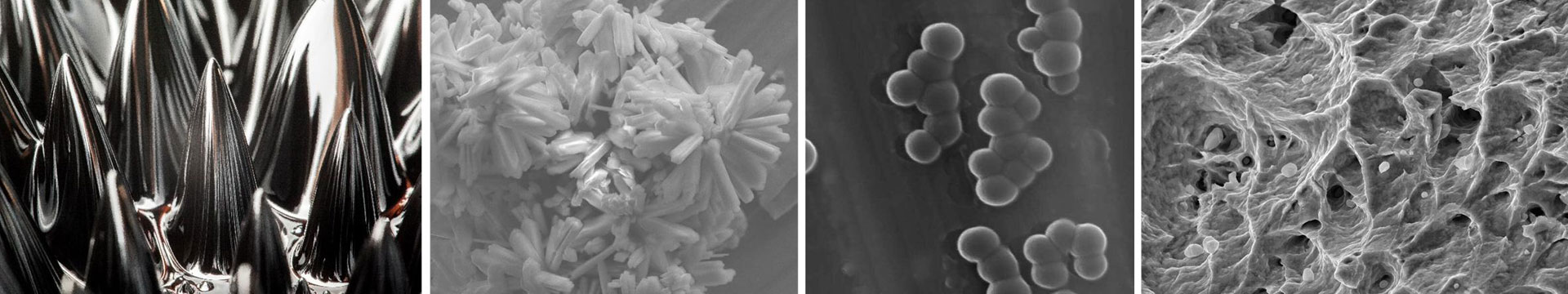

The research activities focus on development and characterization of new magnetic materials which can be potentially used in technical practice. Special attention is devoted to nanocomposites and nanoparticle systems with the building blocks in the range 1 – 100 nanometers (10-9 – 10-7 m).

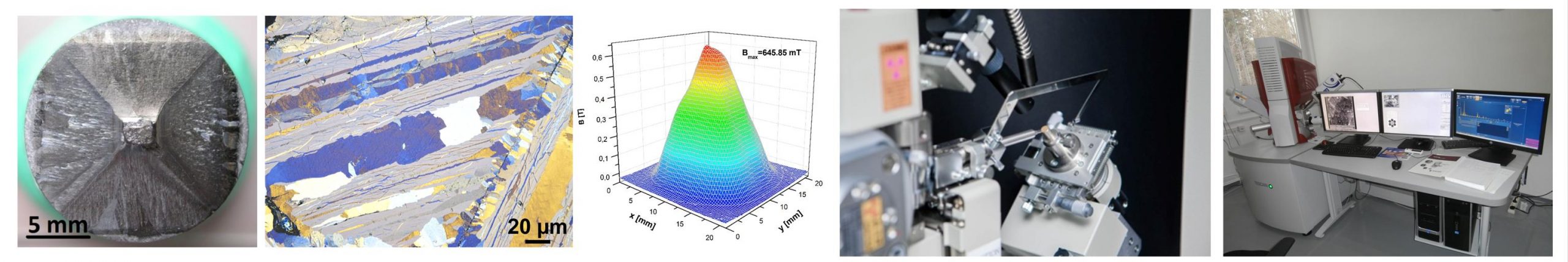

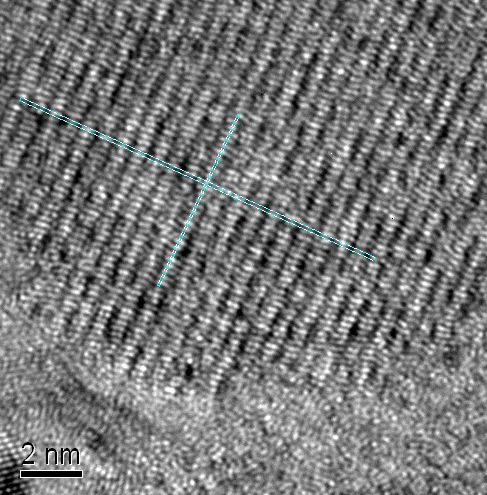

Our long-term interest is focused on nanocrystalline Fe-based metallic alloys prepared by a method of controlled crystalization of amorphous precursors. Besides high magnetic induction values, these alloys show particularly good soft magnetic properties (high permeability, low values of coercive field and premagnetization losses). This combination makes them attractive materials for use in several technical applications such as high-frequency transformers, magnetic sensors, various components of telecommunication and electronic devices, or magnetic shielding. Regarding the potential use of these materials at elevated temperatures, interesting results have been obtained after substituting a portion of the iron atoms with cobalt in original three-component FeNbB alloys. We have obtained the stability of good soft magnetic properties up to temperatures exceeding 500 °C in these alloys. Furthermore, after their heat treatment in a longitudinal magnetic field, we have obtained material with the coercive field of 3 A/m, which is a record low value for HITPERM-type alloys.

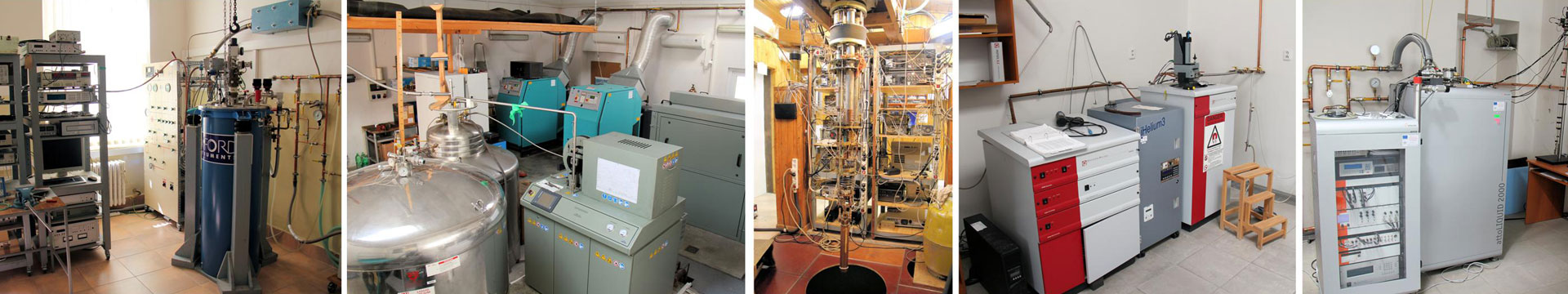

The utilization of heat treatment of nanocrystalline magnetic materials in an external magnetic field for the purpose of tailoring their properties is one of the main current research objectives for the department. The department belongs to the European consortium GAMAS (“GROUP FOR THE APPLIED MAGNETOSCIENCES”) and also participates in application oriented research focusing on new magnetic materials development for industrial sensor systems.

HRTEM micrograph of FeNiNbB nanocrystalline alloy

Part of the research activities is devoted to Fe(Co)Pt-based hard magnetic nanocomposites where the L10 face-centered tetragonal FePt phase with very large magnetocrystalline anisotropy (K~7 MJ/m3) assures excellent hard magnetic characteristics. On the other hand, our recently developed nanocrystalline FeNi-based alloys represent an

example of an extremely soft magnetic material with the coercive field value below 1 A/m, which is more than a million-fold lower value as compared to that for Fe(Co)Pt-based nanocomposites.

The department staff has recently concentrated its attention also on the development of new materials for magnetic refrigeration. This unconventional cooling technology is based on using the magneto-caloric effect occurring under adiabatic conditions. Here the material temperature change is caused by an external magnetic field change. If magnetic material is exposed to an external magnetic field, then the reduction in magnetic spin entropy results in an increase of lattice entropy, which shows itself in rising temperature while demagnetization causes temperature decreases. Our recent results have shown that the systems of ultra-fine superparamagnetic particles show prospective magneto-caloric properties at low temperatures. By coupling spins into a superparamagnetic cluster, magnetic moments can be more easily aligned into a direction of the applied field than in paramagnetic systems, and consequently the spin entropy can change markedly under the influence of a lower external field. The department staff has also been developing iron-based amorphous and nanocrystalline alloys for magnetic refrigeration at room temperature. These alloys are characterized by relatively low price, good chemical stability and the possibility to control the Curie temperature. This makes them interesting candidates

for magneto-caloric applications despite the lower values of magnetic entropy change as compared to those found in rare earth based materials.

Contact

Contact Intranet

Intranet SK

SK