Our scientists have developed a new efficient method of superconductor production

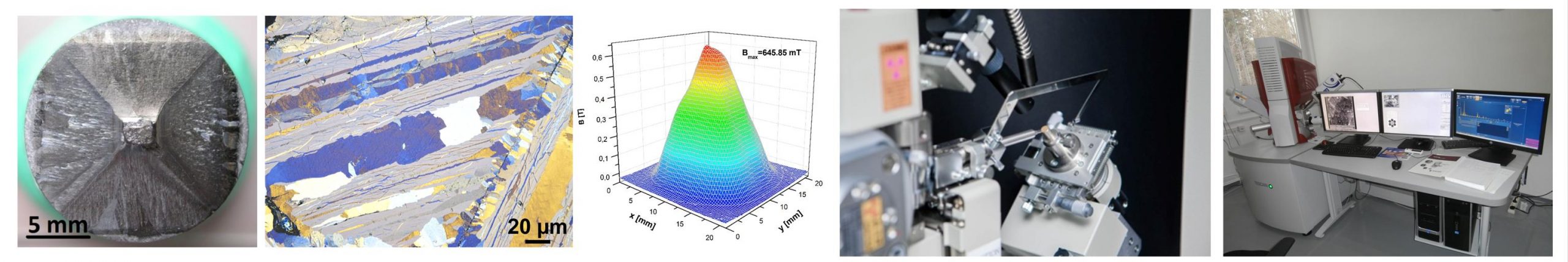

Research team from the Institute of Experimental Physics SAS developed a new innovative method of producing massive monocrystalline GdBCOAg superconductors. These types of superconductors are used in the field of high-current electrical engineering as superconducting permanent magnets. They can be also used in the construction of rotating electric machines, frictionless bearings, levitation transport devices or in the production of devices for magnetic drug delivery. In addition to several technical advantages, the new method of Slovak scientists reduces production costs and increases production yield. SAS is looking for industrial partners for licensing/selling the given solution.

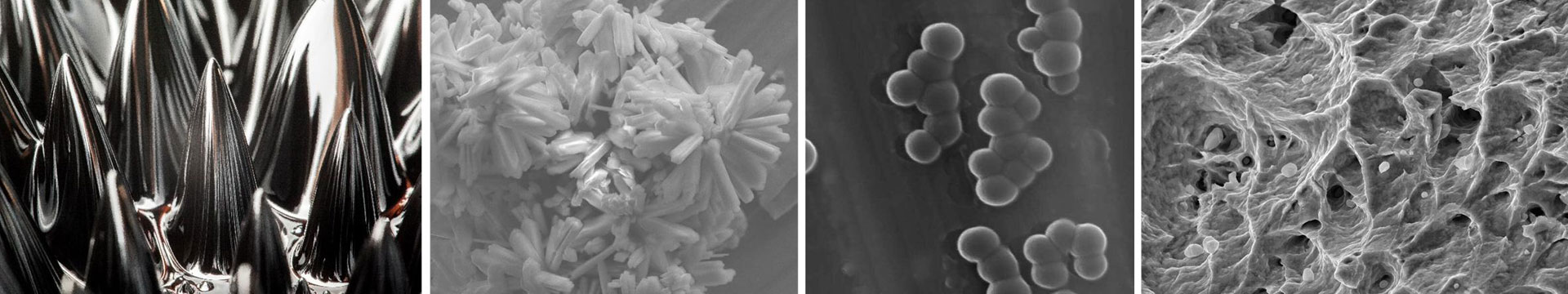

The production of monocrystalline GdBCOAg superconductor is based on the growth of a crystal from a molten chemical mixture. “Currently, cerium in the form of cerium dioxide is used during the production of such superconductors, but the result of this process is an excess of copper oxide, which prevents the crystal from growing sufficiently. The remaining melt subsequently solidifies around the perimeter of the crystal, and since it has a different thermal expansion than a massive crystal, it can lead to the formation of unwanted cracks in the crystal,” explains co-author of the patent Ing. Pavel Diko, DrSc, head of the Department of Materials Physics at IEP SAS and academician of the Learned Society of Slovakia.

A scientific team from Slovakia investigated how it is possible to reduce the amount of solidified melt. They found that barium cerium oxide plays an important role in this process.

“The addition of a specific amount of this chemical compound reduced the volume fraction of the residual solidified melt, compared to an equivalent addition of standard cerium dioxide. This difference significantly increases the size of the resulting massive crystal,” adds the materials physicist.

The innovative approach of scientists from the IEP SAS brings several competitive advantages. It enables the full use of cheaper cerium, the resulting monocrystalline superconductor reaches larger dimensions, the volume fraction of the residual solidified melt is reduced, as well as dilatational thermal stresses at the interface between the crystal and the solidified melt are lower.

For more information, follow the link to the website of the Technology Transfer Office of the SAS Office in the section For companies – Licensing opportunities – Materials.

Sincere congratulations to our colleagues from the Department of Materials Physics!

Original source: SAS News

Contact

Contact Intranet

Intranet SK

SK